Multilayer Stack Piezoelectric Ceramics: Superior Performance Leading the Future Tech Revolution

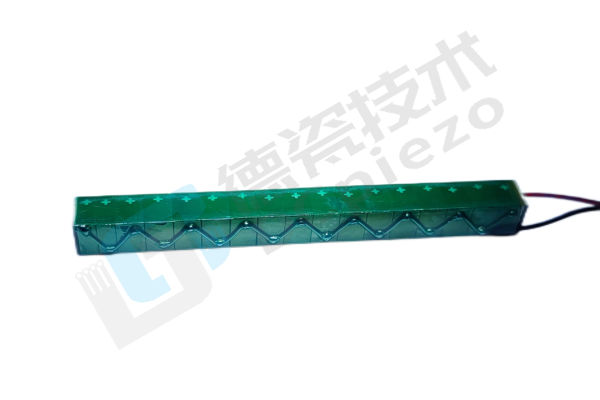

In today’s rapidly advancing technological landscape, breakthroughs in materials science continue to drive industrial transformation. Multilayer stack piezoelectric ceramics (MLSPCs), as a cutting-edge functional material, are emerging as core components in precision actuation, sensors, medical devices, and beyond, propelling innovation across next-generation technologies with their unique structure and exceptional performance.

I. Technical Principles: Unleashing Energy Conversion Potential Through Precision Architecture

The defining characteristic of piezoelectric ceramics lies in their piezoelectric effect—generating electric charges under mechanical stress or deforming in response to electric fields. Traditional single-layer piezoelectric ceramics, constrained by the linear relationship between material thickness and driving voltage, often require hundreds of volts to achieve micron-level displacement. Multilayer stacking technology overcomes this limitation by alternately laminating dozens or even hundreds of ultrathin piezoelectric ceramic layers connected via internal parallel electrodes. Its ingenuity manifests in three key aspects:

Low-Voltage Operation: The multilayer design dramatically increases equivalent capacitance, reducing operating voltages to tens of volts, ensuring compatibility with integrated circuits.

Nanometer-Level Precision: Advanced lamination processes enable displacement resolution down to the nanometer scale, far surpassing conventional piezoelectric materials.

Ultrafast Response: Millisecond-level actuation speeds empower high-speed precision control systems.

II. Performance Advantages: Redefining the Boundaries of Precision Control

Modern industries demand sub-micron precision control. For instance, semiconductor lithography systems require wafer stage positioning accuracy below 1 nanometer—a challenge met by MLSPCs’ three core strengths:

Unmatched Energy Density: Force output per unit volume exceeds 500N, 10 times higher than electromagnetic motors.

Near-Zero Hysteresis: Closed-loop control achieves repeatability errors under 0.1%.

Extreme Environment Stability: Reliable performance in vacuums, strong magnetic fields, and temperature extremes.

These traits make MLSPCs indispensable in spacecraft attitude adjustment, atomic force microscope probe actuation, and other cutting-edge applications.

III. Application Innovations: From Lab Breakthroughs to Industrial Transformation

As fabrication techniques mature, MLSPCs are rapidly expanding their industrial footprint:

Precision Manufacturing: Enabling micron-level chip placement in semiconductor packaging, boosting yield rates by 30%.

Biomedical Advancements: High-resolution ultrasound probes (sub-200μm resolution) enhance early cancer detection.

Consumer Electronics: Tactile feedback modules in smartphones replicate physical button sensations using piezoelectric arrays.

Green Energy Solutions: Multilayer structures improve mechanical vibration-to-energy conversion efficiency to over 65% in energy harvesting systems.

IV. Future Outlook: Pioneering the Smart Materials Revolution

Advancements in nano-lamination and 3D printing are driving MLSPCs toward two evolutionary paths:

Hybridization: Integration with flexible substrates and graphene for wearable biosensors.

Intelligent Systems: Embedded sensors paired with AI algorithms enable self-sensing, adaptive actuators.

According to MarketsandMarkets research, the global piezoelectric ceramics market is projected to exceed $35 billion by 2028, with MLSPCs accounting for over 40% of this growth.

The revolution sparked by multilayer stack piezoelectric ceramics is redefining humanity’s understanding of energy conversion and precision control. From manipulating microscopic realms to enabling intelligent macro-systems, this material bridges fundamental research and industrial applications. As smart manufacturing, digital healthcare, and quantum computing reshape our world, MLSPCs will undoubtedly play an increasingly vital role, propelling human technological progress into uncharted dimensions.