Multilayer Stacked Piezoelectric Ceramics: A Rising Star in Precision Control and Energy Conversion

In fields such as precision engineering, medical devices, aerospace, and intelligent sensing, there is an increasingly urgent demand for high-precision displacement control and efficient energy conversion technologies. As an innovative achievement in piezoelectric materials, multilayer stacked piezoelectric ceramics have become indispensable core components in modern industry due to their unique structural design and performance advantages. This article explores the technical principles, core strengths, and extensive application scenarios of multilayer stacked piezoelectric ceramics, revealing their potential in future technological development.

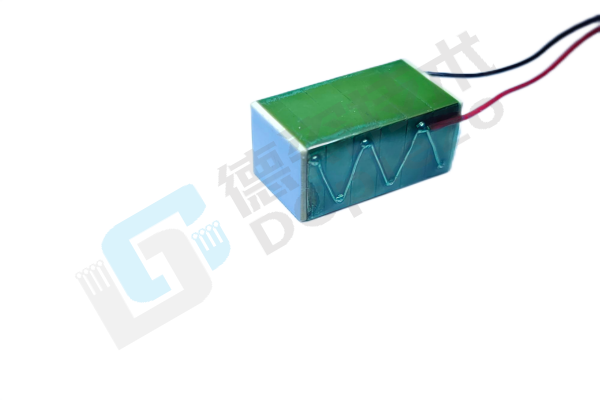

I. Multilayer Stacked Structure: Breaking Through Limitations of Traditional Piezoelectric Ceramics

While traditional piezoelectric ceramics possess the characteristic of mutual conversion between electrical and mechanical energy, they face two major challenges in practical applications: limited displacement of single-layer materials (typically micron-level) and high driving voltage requirements (hundreds or even thousands of volts). The emergence of multilayer stacking technology has achieved a quantum leap in performance by alternately stacking dozens to hundreds of ultra-thin piezoelectric ceramic layers with embedded internal electrodes.

Technical Principle:

Each piezoelectric ceramic layer generates micro-deformation under electric field, with the series connection of multiple layers multiplying the total displacement. Meanwhile, the extremely small interlayer spacing (typically 20-100 μm) allows driving voltage to be significantly reduced to tens of volts, dramatically improving device safety and energy efficiency. For instance, while traditional single-layer piezoelectric ceramics require 500V driving voltage, equivalent performance can be achieved with multilayer stacked structures using less than 50V.

II. Core Performance Advantages: Integration of Precision, Efficiency, and Reliability

High-precision displacement control

The multilayer stacked structure enables nanometer-level resolution position adjustment, with repeat positioning accuracy reaching ±0.1%. This characteristic makes it a critical actuating component in high-precision scenarios such as optical focusing systems and semiconductor lithography machine positioning platforms.

Fast response and high-frequency characteristics

Benefiting from low capacitance design and compact structure, the response time of multilayer stacked piezoelectric ceramics can be as short as millisecond-level, supporting kilohertz-level high-frequency vibrations. For example, in ultrasound medical equipment, it can generate stable high-frequency mechanical waves for precise in vivo imaging or lithotripsy therapy.

High energy density and long lifespan

Through optimization of ceramic material formulas (such as PZT, PMN-PT) and sintering processes, modern multilayer stacked piezoelectric ceramics achieve over 80% energy conversion efficiency with excellent anti-fatigue performance, offering cyclic service life exceeding 1 billion operations.

III. Application Scenarios: From Industrial Automation to Green Energy

Precision manufacturing and inspection

● In semiconductor manufacturing: High-precision displacement stages driven by multilayer stacked piezoelectric ceramics for wafer alignment and lithography machine mask positioning

● In atomic force microscopy (AFM): Providing nanometer-level scanning control for probes to facilitate material surface topography analysis

Medical and life sciences

● Core component of ultrasound transducers: Generating acoustic waves through high-frequency vibrations for B-ultrasound imaging and ultrasonic scalpels

● Minimally invasive surgical robots: Driving micro-manipulators to perform precise intravascular operations

Energy recovery and green technologies

● Vibration energy harvesting: Converting mechanical vibrations (e.g., bridges, vehicle bumps) into electricity to power wireless sensors

● Piezoelectric energy-harvesting floors: Applied in high-traffic areas for efficient capture of pedestrian energy

Consumer electronics and smart devices

● Smartphone camera autofocus modules: Replacing traditional voice coil motors to achieve faster and quieter focusing

● Haptic feedback devices: Simulating realistic tactile sensations through micro-vibrations to enhance AR/VR interaction experiences

IV. Technical Challenges and Future Trends

Although significant progress has been made in multilayer stacked piezoelectric ceramics, the industry still faces challenges:

● Material uniformity: Sintering ultra-thin ceramic layers requires avoiding interlayer cracking and electrode penetration

● High-temperature stability: Piezoelectric performance tends to degrade in extreme environments (e.g., aerospace applications)

● Cost control: Precision lamination processes and precious metal electrodes (e.g., silver-palladium) result in high manufacturing costs

Future development directions include:

● New material development: Industrialization of lead-free piezoelectric ceramics (e.g., KNN-based materials) to meet environmental regulations

● Process innovation: Adoption of 3D printing technology or tape casting processes to achieve more complex layered structures

● Intelligent integration: Integrated design of built-in sensors and drive circuits to enhance system response speed and reliability

Multilayer stacked piezoelectric ceramics are redefining modern industry's pursuit of power and precision through their exceptional control capabilities and efficient energy conversion characteristics. With continuous breakthroughs in materials science and manufacturing technologies, this technology is expected to unleash greater potential in robotics, new energy, and smart healthcare. As professional piezoelectric ceramic manufacturers, we will continue to drive innovative iterations of multilayer stacking technology, providing global clients with more efficient and reliable solutions to empower the precision engineering revolution in the intelligent era.