Multilayer Stacked Piezoelectric Ceramics: Driving the Development of Smart Manufacturing and Green Energy

——Precision Material Innovation Drives Industrial Transformation and Upgrading

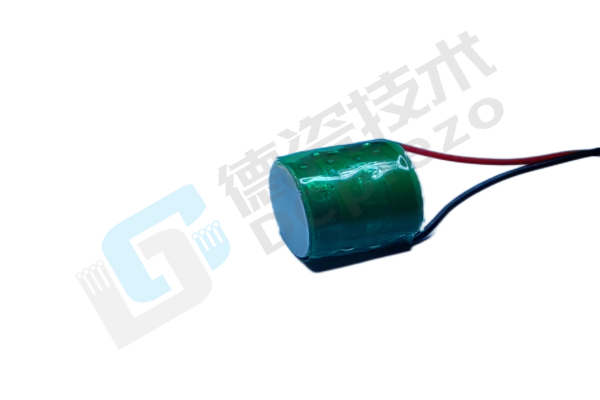

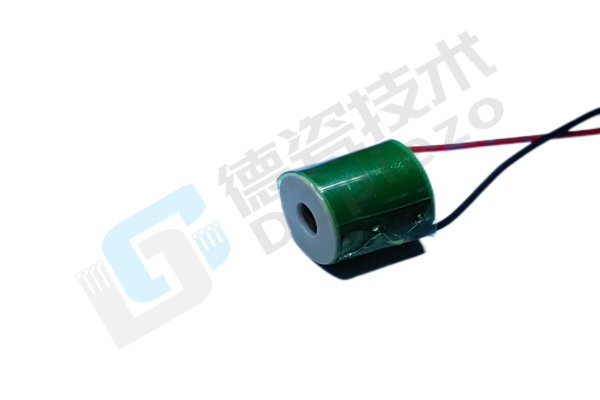

Under the global wave of Industry 4.0 and carbon neutrality goals, functional materials represented by multilayer stacked piezoelectric ceramics are becoming the technological cornerstone in precision manufacturing and clean energy fields. As a core component combining high-efficiency electromechanical conversion performance with structural adaptability, its innovative applications are redefining the technical boundaries of high-end equipment and energy systems.

I. Precision Control Revolution: The Core Power Source of Smart Manufacturing

● Micron-Level Accuracy Empowers Industrial Upgrading

The multilayer stacked structure amplifies nanoscale deformation accumulation under electric field driving through vertical stacking of piezoelectric ceramic units. In scenarios such as semiconductor lithography machines and precision optical platforms, it achieves displacement control accuracy at the 0.1μm level, improving chip manufacturing yield by over 30%.

● Dynamic Response Breaks Equipment Limits

Compared to traditional electromagnetic drives (response time 10-100ms), the microsecond-level response characteristics of stacked piezoelectric ceramics enable industrial robot end-effectors to achieve action frequencies exceeding 500Hz, providing core kinetic energy for high-speed placement equipment in the 3C electronics industry.

● Self-Sensing Closed-Loop System Construction

Intelligent stacked modules integrating stress-charge bidirectional sensing functions have realized real-time dynamic compensation in CNC machine tool chatter suppression systems, reducing machining surface roughness to Ra0.02μm levels.

II. Green Energy Transition: From Energy Conversion to System Optimization

● New Paradigm for Distributed Energy Harvesting

The multilayer structure based on d33 mode converts environmental vibration energy (0.5-5 m/s²) into electricity, enabling self-powered operation in smart grid monitoring terminals. Experimental data show that piezoelectric energy harvesting devices deployed along railway tracks generate up to 120Wh/km daily.

● Wind Power System Efficiency Multiplier

Piezoelectric ceramic-driven pitch control systems with response speeds improved to 50ms-level increase annual power generation of 5MW turbines by 8%-12% under turbulent conditions. Meanwhile, blade health monitoring systems using embedded piezoelectric sensors provide structural damage warnings 1,500 hours in advance.

● Key Breakthrough in Hydrogen Energy Industry Chain

In proton exchange membrane electrolyzers, stacked piezoelectric ceramics precisely control electrode plate spacing to 10μm-level, pushing hydrogen production efficiency beyond 75% while reducing energy consumption to 4.3kWh/Nm³.

III. Sustainable Manufacturing: From Material Innovation to Ecological Closed Loop

● Eco-Friendly Process Breakthrough

The multilayer stacked manufacturing process adopting low-temperature co-firing technology (sintering temperature <900°C) saves 40% energy compared to traditional methods. By replacing precious metals with silver electrodes, per-unit production costs decrease by 25%.

● Full Lifecycle Management

Material composition optimization (e.g., bismuth-layered structures replacing partial PZT systems) extends product lifespan to 10^9 cycles. Discarded ceramics can be crushed and reused as microwave dielectric substrates.

Conclusion: Innovative Materials Define Industrial Futures

Driven by both industrial internet and new energy revolutions, multilayer stacked piezoelectric ceramics are evolving from single-function components to system-level solutions. As a piezoelectric ceramic manufacturer with 15 years of industry expertise, we continuously advance material formulation innovation and process optimization. Through more efficient and reliable customized products, we empower partners to build technical barriers in precision manufacturing and clean energy fields.Visit our official website or contact our technical team to access industry white papers and customized solutions.