Exploring the Boundless Potential of Multilayer Stack Piezoelectric Ceramics: The Core Force Driving Future Precision Technology

In the pursuit of extreme precision and high-efficiency drive at the technological frontier, one material is quietly transforming the performance boundaries of numerous high-end devices—it is multilayer stack piezoelectric ceramics. As the pinnacle of technological crystallization in the piezoelectric ceramic field, the multilayer stack structure grants traditional piezoelectric materials unprecedented performance leaps, unlocking boundless potential for micro/nano manipulation, ultra-fast response, and high energy density. As a professional force deeply committed to the R&D and manufacturing of piezoelectric ceramic materials and devices, we are dedicated to transforming this "boundless potential" into our clients' core competitiveness.

I. What Are Multilayer Stack Piezoelectric Ceramics?

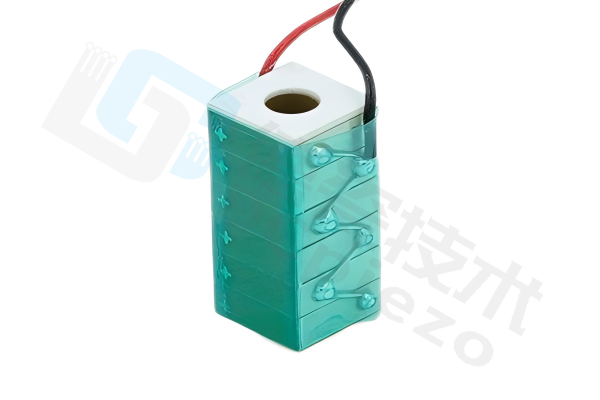

Piezoelectric ceramics are smart functional materials capable of converting electrical energy into mechanical energy and vice versa. Multilayer stack piezoelectric ceramics, however, integrate dozens or even hundreds of extremely thin piezoelectric ceramic layers with internal electrodes alternately stacked into a single unit through precise lamination and co-firing technology. This structural design ingeniously overcomes the limitations of single-layer piezoelectric ceramics—small displacement and high drive voltage—achieving:

• Low-Voltage Drive, Large Displacement Output: Generates precise displacements of tens to hundreds of micrometers under relatively low operating voltages (typically tens to hundreds of volts).

• High Response Speed: Uniform internal electric field distribution enables response times in the microsecond or even nanosecond range, meeting ultra-fast dynamic control demands.

• High Output Force and Energy Density: The synergistic action of the multilayer structure produces enormous thrust (up to thousands of Newtons) with high energy conversion efficiency.

• High Positioning Accuracy and Resolution: Displacement control accuracy reaches nanometer or even sub-nanometer levels, making it a core component for precision positioning.

• Compact Structure, High Reliability: The integrated design ensures a small footprint. Combined with advanced material formulations and manufacturing processes, it exhibits excellent long-term stability and fatigue resistance.

II. Unlocking Boundless Application Potential

The exceptional performance of multilayer stack piezoelectric ceramics makes them indispensable as the "power heart" and "precision hand" in numerous high-tech fields:

• Semiconductor Manufacturing & Precision Inspection: Drives micro-stages in lithography machines, wafer alignment platforms, and probe stations, enabling nanometer-level precise positioning and rapid step-and-scan operations. It is a key enabler for the continued advancement of Moore's Law.

• Precision Optics & Laser Technology: Used for rapid laser beam steering, focusing, and shaping (e.g., driving adaptive optics deformable mirrors), nanometer-level fine-tuning of optical components, interferometer phase modulation, etc., enhancing optical system performance.

• Biomedical Engineering: Drives precision pumps/valves in microfluidic chips, cell manipulation micro-needles, high-resolution ultrasound imaging probes, and delicate instruments in surgical robots, advancing precision medicine.

• Aerospace & High-End Manufacturing: Applied in active vibration control for aircraft, precision fuel injection control, attitude adjustment actuators for micro/nano satellites, and micro-feed systems for precision machine tools.

• Scientific Instruments & Fundamental Research: Serves as the core scanner in Scanning Probe Microscopes (SPM) and Atomic Force Microscopes (AFM), enabling atomic-resolution imaging and manipulation.

• Consumer Electronics (Emerging Field): Shows potential in micro speakers (speaker drivers), haptic feedback, and precision focus motors (e.g., for mobile phone lenses).

III. Our Core Advantages: The Foundation for Harnessing Boundless Potential

Deci Tech: We deeply understand the intricacies and challenges of multilayer stack piezoelectric ceramics. Leveraging:

• Advanced Material R&D Capabilities: Optimize ceramic formulations to pursue higher piezoelectric coefficients (d33, g33), electromechanical coupling coefficients, lower dielectric losses, and superior temperature stability.

• Precision Lamination Manufacturing Process: Master the full suite of core processes—from tape casting, precision printing, lamination to high-temperature co-firing (LTCC/HTCC)—ensuring dense interlayer bonding, excellent electrode conductivity, and top-tier product consistency and reliability.

• Stringent Quality Control System: Implement strict testing throughout the entire process, from raw materials to finished products, ensuring every stack ceramic boasts exceptional performance and extended service life.

• Powerful Customization Service: Provide tailor-made stack piezoelectric ceramic actuator solutions based on customers' specific application scenarios (e.g., displacement, force, voltage, frequency, size, environmental requirements).

• Profound Technical Support: Our engineering team not only supplies products but also offers application selection guidance, drive solution recommendations, and system integration support.

Multilayer stack piezoelectric ceramics are continuously pushing the boundaries of technology with their unparalleled precision, speed, and powerful drive. The "boundless potential" they embody is transforming into a key driving force for innovation and upgrading across industries. (Guangdong Deci Technology Co., Ltd.), as an explorer and practitioner in this field, remains steadfastly focused on deepening material science and refining manufacturing processes. We look forward to collaborating with you to unlock the deeper potential of multilayer stack piezoelectric ceramics and propel the future forward with precision!

Choose [Deci Tech], Choose the Boundless Potential of Precision Drive!

Contact Us: +86 13267150099