Multilayer Stack Piezoelectric Ceramics: A Revolutionary Innovation in Materials Science

In the field of precision actuation and control technology, piezoelectric ceramics have become an indispensable core component due to their excellent electromechanical conversion performance. However, traditional single-layer piezoelectric ceramics have certain limitations in output displacement and driving force, making it difficult to meet the increasing demand for high-precision, high-thrust applications. The emergence and development of Multilayer Stack Piezoelectric Ceramics represent a major innovation in materials science, skillfully breaking through this bottleneck and opening a new chapter for modern precision engineering.

I. Technical Core: The Power of Stacking

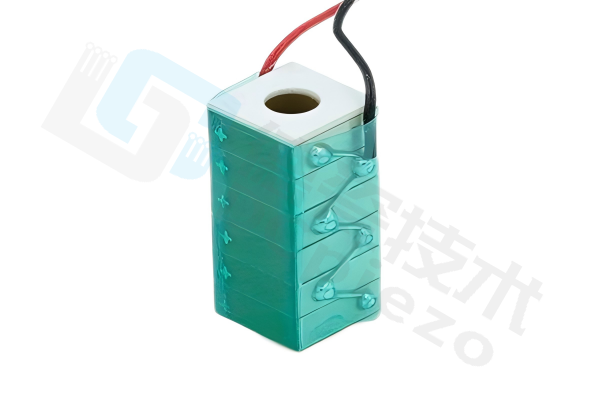

The core secret of multilayer stack piezoelectric ceramics lies in their unique structural design. It is not a single-thickness ceramic block, but a monolithic structure formed by stacking dozens or even hundreds of extremely thin piezoelectric ceramic layers (typically tens to over one hundred micrometers thick) alternately with internal electrode layers through precision processes, followed by co-sintering. This structural design brings revolutionary performance enhancements:

1、Low-voltage driving, high displacement output: Under the same operating voltage, the multilayer stacked structure efficiently superimposes the tiny displacements generated by each ceramic layer, thereby outputting total displacements several times or even dozens of times greater than single-layer ceramics of equal volume. This significantly reduces the demand for high-voltage driving power supplies (typically requiring only tens to over one hundred volts), improving system safety and ease of use.

2、High response speed and high frequency: Due to the minimal thickness of each ceramic layer, their natural resonant frequency is very high. The integrated device maintains large displacement output while possessing excellent rapid response capability (microsecond-level response), enabling high-frequency dynamic operations.

3、High driving force output: The multilayer stacked structure greatly increases the effective actuation area, allowing the device to generate greater thrust (up to hundreds of Newtons or higher), meeting high-load demands such as precision positioning and active vibration damping.

4、High energy density and high efficiency: The structural design optimizes electric field distribution, improves the conversion efficiency from electrical to mechanical energy, outputs greater mechanical work per unit volume or unit weight, and significantly enhances energy density.

5、Compact structure, flexible design: Achieves high performance within a relatively small space, facilitating integration into various precision equipment. Its shape (square, circular, ring-shaped, etc.) and size can be flexibly customized according to specific applications.

II. Revolutionary Significance: Pushing the Boundaries of Precision Technology

The application of multilayer stacking technology marks a milestone in the evolution of piezoelectric ceramic materials from single-function components to high-performance integrated actuators. Its "innovative" aspects are reflected in:

● Performance limit breakthrough: Resolves the contradiction of traditional piezoelectric ceramics where "high displacement requires high voltage" or "high voltage brings large displacement but slow response/low thrust," achieving the perfect combination of "low voltage, large displacement, fast response, high thrust".

● Application scenario expansion: Significantly expands the application scope of piezoelectric ceramics from simple sensors, acoustic devices, etc., to demanding high-tech fields such as precision positioning platforms (nanometer-level accuracy), semiconductor lithography and packaging equipment, precision optical adjustment (e.g., adaptive optics), biomedical instruments (e.g., micromanipulation, cell puncture), active vibration control, microfluidic control, and fuel injection systems.

● System integration simplification: Low-voltage driving characteristics simplify supporting power supply design, reduce system complexity and cost, and promote the adoption of piezoelectric technology in broader industrial fields.

III. Quality Assurance: Precision Challenges in Manufacturing Processes

Achieving the outstanding performance of multilayer stack piezoelectric ceramics highly depends on advanced material formulations and extremely precise manufacturing processes:

● Ultra-thin tape casting: Preparing ultra-thin ceramic green tapes with uniform thickness and minimal defects is the critical starting point.

● Precision printing and lamination: Internal electrodes (typically silver-palladium alloy) must be accurately printed on each ceramic green layer and undergo high-precision alignment lamination to ensure reliable interlayer connections.

● Co-firing technology: Ceramic layers and metal electrode layers require co-sintering at high temperatures for densification without deformation, delamination, or excessive reactions, placing extremely high demands on material compatibility and sintering process control.

● Poling process: The sintered multilayer blank requires uniform and sufficient polarization under a strong electric field to activate its piezoelectric properties.

Guangdong Deci Technology Co., Ltd. as a professional piezoelectric ceramic manufacturer, deeply understands the challenges and essence of multilayer stacking technology. We rely on:

● Advanced material R&D capabilities: Continuously optimizing piezoelectric ceramic powder formulations to ensure high d33 (piezoelectric constant), high Curie temperature, low dielectric loss, and excellent temperature stability.

● Internationally leading precision manufacturing equipment: Possessing core equipment including high-precision tape casting lines, precision screen printers, automatic stacking systems, and precision sintering furnaces.

● Strict process control and quality systems: Implementing rigorous process control and full-process inspection for each manufacturing step to ensure product performance consistency, reliability, and long service life.

● Profound technical expertise and customization capabilities: Providing professional design support and customized production services based on customers’ specific application requirements (displacement, force, frequency, size, environment, etc.).

Multilayer stack piezoelectric ceramics, with their exquisite structural design and breakthrough performance, rightfully stand as a revolutionary innovation where materials science empowers precision engineering. They not only represent the pinnacle of current piezoelectric ceramic technology but also serve as a key driver for continuous innovation in future frontier fields such as smart manufacturing, precision instruments, and biomedicine.

Deci Technology will continue to deepen its expertise in multilayer stack piezoelectric ceramic technology, committed to providing customers with high-performance, stable, and reliable core piezoelectric components and solutions. We will collaborate with partners to jointly advance the boundaries of precision technology, transforming "the power of materials" into "the momentum of innovation".