In modern industry and technology, where extreme precision and efficiency are paramount, the demands for "motion control" have reached unprecedented levels—from nanoscale manipulations to high-speed, precision drives in the macroscopic world. Traditional motors and electromagnetic actuators often fall short in many cutting-edge applications due to issues like inertia, backlash, and response delay. It is here that a "secret weapon" based on smart materials plays an irreplaceable role: Multilayer Stack Piezoelectric Ceramics.

As a professional manufacturer of piezoelectric ceramics, we will unveil the mysteries of this precision technology and explain why it has become the core key in the field of precision control.

I. What are Multilayer Stack Piezoelectric Ceramics?

To understand the "stack," one must first understand the "piezoelectric effect." The piezoelectric effect refers to the phenomenon where certain specific materials (such as PZT - Lead Zirconate Titanate ceramic) undergo minute deformation when an electric field is applied (inverse piezoelectric effect), and conversely, generate an electric charge when mechanical stress is applied (direct piezoelectric effect). While a single piezoelectric ceramic wafer offers rapid response, its deformation is very limited, typically only a few thousandths of a millimeter, severely restricting its direct application. To solve this problem, Multilayer Stack Piezoelectric Ceramics emerged. Utilizing advanced co-firing technology, they alternate and stack hundreds or even thousands of extremely thin piezoelectric ceramic layers with internal electrodes, connecting them in parallel. When a voltage is applied, each ceramic layer produces a tiny displacement; these minuscule displacements accumulate layer by layer, ultimately resulting in a significant total displacement overall. This design is like a well-trained team where each member takes a small step, allowing the entire team to advance a great distance.

II. Why is it the "Secret Weapon for Precision Control"? – Five Core Advantages

Multilayer Stack Piezoelectric Ceramics are hailed as a "secret weapon" due to their unparalleled combination of performance characteristics:

1.Ultra-High Resolution at the Nanometer and Sub-Nanometer Level

This is its most core advantage. Through precise voltage control, extremely fine adjustment of displacement can be achieved, with resolution easily reaching the nanometer level or even higher. This means that in optical focusing, microscopic manipulation, and precision machining, it can achieve the ultimate accuracy where "a minute error can lead to a massive discrepancy."

2.Extremely Fast Response Speed in Microseconds

The deformation of piezoelectric ceramics stems from the displacement of internal ions under an electric field. This process involves almost no mechanical inertia, resulting in extremely short response times, reaching microseconds or even nanoseconds. This is crucial for applications requiring high-frequency vibration, fast valve switching, or active vibration damping, surpassing what traditional electromagnetic actuators can achieve.

3.High Output Force (Thrust)

Despite its compact size, it can generate impressive force. Due to the high stiffness of the ceramic material itself and the stack structure operating under pre-load stress, it can generate thrust forces up to hundreds or even thousands of Newtons. It can handle delicate "embroidery" tasks as well as serve as a "powerhouse."

4.Non-Magnetic, Frictionless, and Zero Backlash

The entire actuation process is based solely on the material's own deformation, without any traditional mechanical transmission components (such as gears, lead screws). Therefore, it is free from friction and wear, has no backlash, and generates no electromagnetic interference. This offers decisive advantages in vacuum environments, MRI rooms, or semiconductor manufacturing requiring extreme cleanliness.

5.High Energy Efficiency and Stability

When statically holding a displacement, piezoelectric ceramics theoretically consume almost no current (only minimal leakage current exists), resulting in very low energy consumption. Furthermore, polarized and process-optimized piezoelectric ceramics exhibit excellent long-term stability and anti-aging performance, ensuring reliable operation over extended periods.

III. Unveiling the Core of Manufacturing: Precision Mastery from Material to Process

As a manufacturer, we deeply understand that exceptional performance stems from precise control over every manufacturing step.

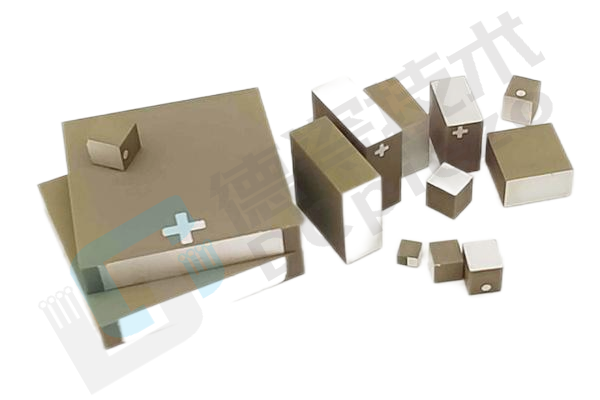

● Powder Preparation and Formulation: Using high-purity, ultra-fine PZT powders and unique doping modification technologies to optimize piezoelectric constants, electromechanical coupling coefficients, and temperature stability.

● Tape Casting: Forming ceramic slurry into uniform ceramic sheets, only tens of microns thick, using a tape caster. This is the foundation for creating multilayer stacks.

● Precision Printing and Lamination: Using screen-printing technology to precisely print internal electrode patterns onto the ceramic sheets, then aligning and laminating them accurately, like making a "thousand-layer cake."

● Co-firing Technology: This is the most critical and challenging process. The laminated green bodies are sintered in a single high-temperature step, firmly bonding the ceramic layers and internal electrodes (typically silver-palladium alloy) into a dense monolithic structure, ensuring mechanical strength and electrical performance.

● Polarization and Aging: The sintered ceramic requires "polarization" under a high-voltage electric field to activate its piezoelectric properties. Subsequently, aging treatment is performed to stabilize its performance.

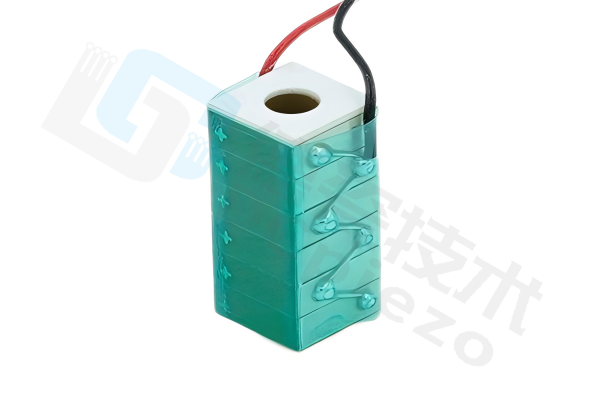

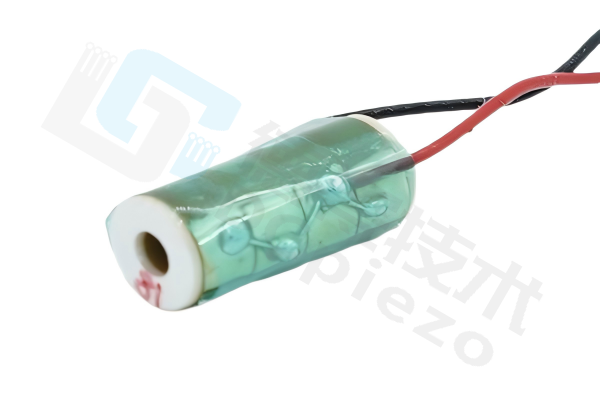

● Encapsulation and Testing: To protect the brittle ceramic body and facilitate installation, precise metal or polymer encapsulation is typically applied. Before leaving the factory, each stack piezoelectric ceramic undergoes rigorous performance testing, including displacement, capacitance, loss, and insulation resistance.

IV. The Stage for Application: Demonstrating Its Capabilities

Leveraging the above advantages, Multilayer Stack Piezoelectric Ceramics have become indispensable core components in numerous high-tech fields:

● Precision Positioning and Nano-Manipulation: Applied in Scanning Probe Microscopes, adaptive optics systems for astronomical telescopes, fiber optic alignment in telecommunications, and wafer stages in chip manufacturing lithography systems.

● Active Vibration Control: Used in precision machine tools, aerospace structures, and high-precision measuring instruments, actively canceling external disturbances by generating counter-vibrations, achieving a "steadfast as Mount Tai" stability effect.

● Fuel Injection Systems: In common rail diesel engines, piezoelectric fuel injectors control fuel injection with extremely high speed and precision, significantly improving engine efficiency and reducing emissions.

● Ultrasonic Medical and Industrial Equipment: Serving as the core of ultrasonic transducers for medical ultrasound imaging, ultrasonic lithotripsy, as well as industrial ultrasonic welding, cleaning, and processing.

● Valves and Fluid Control: Enabling high-precision, high-frequency switching control for minute flow rates, applied in analytical instruments, semiconductor processes, and the pharmaceutical industry.

V. Partner with a Professional Manufacturer to Open a New Era of Precision Actuation

Multilayer Stack Piezoelectric Ceramics, a product embodying the culmination of materials science, electronics technology, and precision manufacturing processes, are redefining the boundaries of "precision control" with their unique charm. They are not only a secret weapon for engineers but also a key force driving technological progress and industrial upgrading. As a professional manufacturer with years of deep expertise in the piezoelectric field, we are committed to providing customers with multilayer stack piezoelectric ceramic solutions, ranging from standard products to fully customized ones. We possess advanced production equipment, a strict quality control system, and an experienced technical team, ensuring that every product delivers outstanding performance and reliable quality.

If you are seeking an actuation solution that can break through precision limits and enhance equipment performance, Multilayer Stack Piezoelectric Ceramics are your ideal choice. Please feel free to contact us. Let us empower your project with our professional "secret weapon" and together open a new era of precision actuation