In today's rapidly advancing fields of intelligent manufacturing, medical surgery, aerospace, and precision detection, robots are evolving from simple repetitive executors into intelligent partners with highly sensitive environmental perception and adaptive operational capabilities. One of the core drivers behind this evolution lies in the continuous advancement of their "nerve endings"—sensors and actuators. Among these technologies, Multilayer Stack Piezoelectric Ceramics, with their unique performance advantages, are quietly reshaping the boundaries of robotic perception and execution precision, becoming a key enabling component for high-end robotic systems to achieve breakthrough performance.

I. Core Technology Explained: What Are Multilayer Stack Piezoelectric Ceramics?

Piezoelectric ceramics are intelligent materials exhibiting the piezoelectric effect. They can generate electric charge under applied mechanical stress (direct piezoelectric effect) or produce micro-deformation or force under an applied electric field (inverse piezoelectric effect). This characteristic makes them an ideal bridge connecting the "electrical" world with the "force/motion" world.

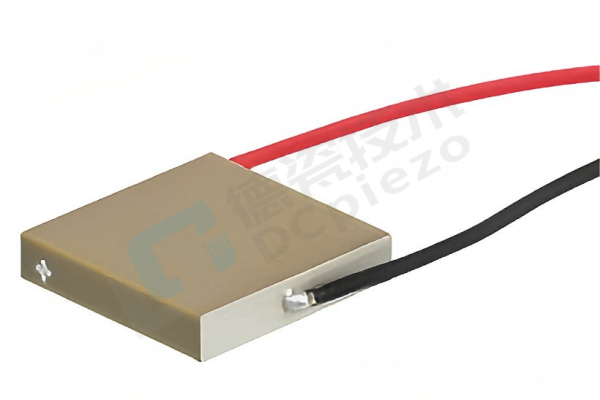

Traditional monolithic piezoelectric ceramic actuators produce limited displacement under driving voltage (typically sub-micron), restricting their application in scenarios requiring large strokes and high output force. Multilayer Stack Piezoelectric Ceramics technology elegantly resolves this contradiction through innovative internal structural design.

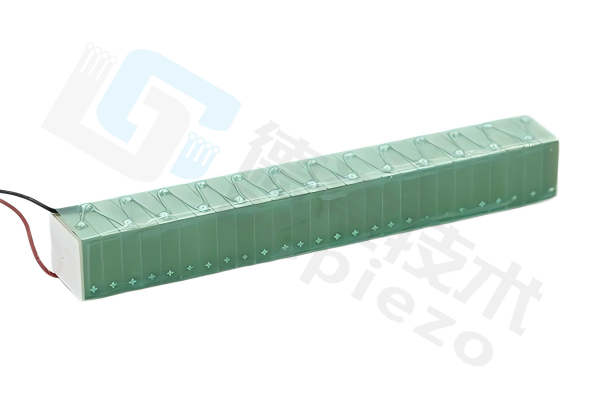

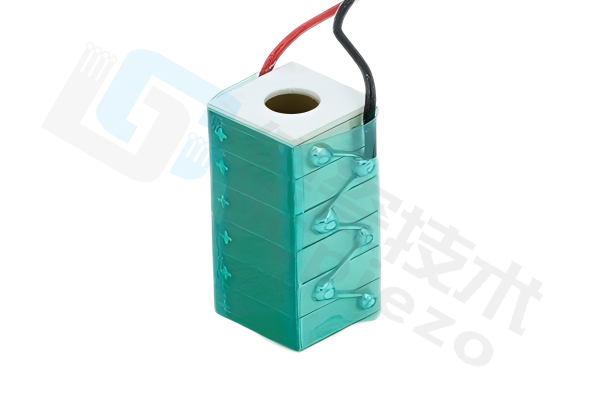

The core principle involves alternating and stacking dozens or even hundreds of extremely thin piezoelectric ceramic layers (each as thin as tens of microns) with internal electrodes, followed by co-firing into an integrated monolithic structure. Under voltage drive, each ceramic layer generates a minute longitudinal expansion or contraction. Since all layers are electrically connected in parallel (with consistent electric field direction) and mechanically connected in series, these micro-deformations efficiently accumulate along the stacking direction. This results in substantial overall displacement output (up to hundreds of microns) while maintaining extremely high output force (hundreds to thousands of Newtons).

This structure endows multilayer stack piezoelectric ceramics with three significant advantages:

1.Low Voltage Drive, High Displacement Output: Only tens to two hundred volts of driving voltage are needed to achieve displacement an order of magnitude greater than traditional single-layer structures, enabling safer and more convenient system integration.

2.Ultra-High Response Speed and Frequency: The conversion from electrical signal to mechanical motion is nearly instantaneous (response time in the microsecond range), enabling high-frequency precision vibration or positioning above kHz.

3.Nanometer Resolution and High Stiffness: Displacement control resolution can reach sub-nanometer levels. The inherent high structural stiffness is insensitive to external load variations, ensuring exceptional positioning stability and repeatability.

II. Empowering Robotics: The Leap from Precision Perception to Active Adaptation

Integrating multilayer stack piezoelectric ceramics into robotic systems significantly enhances capabilities across two primary dimensions: "Active Sensing" and "Precision Actuation."

1.As Ultra-Sensitive Perceptual "Nerves"

Utilizing the direct piezoelectric effect, the multilayer stack structure serves as a highly sensitive dynamic force, vibration, or tactile sensor.

● Fine Tactile Feedback: Integrated into robotic fingertips or surgical instrument tips, it can perceive and quantify micro-forces during object contact (e.g., gripping an egg, touching tissue) in real-time, digitizing "touch" to achieve truly compliant grasping and safe human-robot interaction.

● Condition Monitoring & Predictive Maintenance: Mounted on robot joints or critical structures, it continuously monitors micro-vibration spectra. Any anomalous vibrations (e.g., from gear wear, bearing faults) are precisely captured, enabling early fault warning and predictive maintenance to enhance equipment reliability and lifespan.

2.As High-Speed Precision Actuation "Muscles"

Utilizing the inverse piezoelectric effect, multilayer stack ceramics are irreplaceable as precision, rapid micro-displacement actuators.

● Active Vibration Damping & Isolation Platforms: High-speed industrial robots or precision measurement equipment are often affected by self-induced motion or ground vibrations. Active isolation platforms integrated with multilayer piezoelectric ceramics can sense and generate counter-motion in real-time to actively cancel vibrations, creating an ultra-stable "micro-quiet zone" for end-effectors or optical systems, significantly improving machining or measurement accuracy.

● Adaptive Optics & Alignment Systems: In chip lithography, laser processing, or robotic microscopic imaging, they enable rapid micro-adjustment of lens focus, mirror angles, or beam paths, compensating for errors caused by thermal deformation or mechanical drift to ensure processes remain continuously optimized.

● High-Frequency Micro-Manipulation & Processing: They drive ultrasonic cutting/drilling heads for precision work or serve as the core driver for precision dispensing valves/micro-jetting valves, enabling picoliter-level fluid dispensing with ultra-high frequency and consistency, meeting stringent demands in electronics packaging and bioprinting.

● Biomimetic Joints & Actuation: Mimicking the fast, fine motion characteristics of human muscles, they provide compact, efficient, and quiet drive solutions for micro-robotic or biomimetic robotic joints, enabling more flexible and human-like motion performance.

III. Technical Challenges and Our Solutions

Despite the promising outlook, designing and manufacturing multilayer stack piezoelectric ceramics is fraught with challenges: risks of deformation and cracking during thin-layer formation and co-firing processes, control of internal electric field uniformity, reliability under long-term high loads, and thermal management issues—all directly impact the final product's performance and lifespan.

As a professional manufacturer with years of deep expertise in piezoelectric ceramics, Guangdong Deci Technology has established core competencies through continuous R&D:

● Precision Formulation & Tape Casting: Proprietary ceramic powder formulations combined with sub-micron precision tape casting ensure uniform ceramic film thickness with minimal defects.

● Advanced Co-firing & Electrode Technology: Optimized sintering profiles achieve perfect co-firing of ceramic layers and internal electrodes (e.g., silver-palladium alloy), ensuring dense internal structure, strong interfacial bonding, and excellent electrical properties.

● Multilayer Structure Simulation & Design: Finite element analysis tools are used to accurately simulate electric field and stress distribution during the design phase, optimizing layer count and electrode patterns to maximize performance and mitigate failure risks.

● Rigorous Aging & Reliability Testing: Each production batch undergoes extensive testing, including thermal cycling, long-term load endurance, and fatigue life tests, ensuring long-term stability and consistency under various harsh operating conditions.

IV. Future Outlook: Collaborating to Create a New Era for Intelligent Robotics

As robotic applications expand into micro-scale, high-risk, and ultra-precision domains, the demands for sensing sensitivity, execution accuracy, and response speed will know no bounds. Multilayer stack piezoelectric ceramic technology continues to evolve toward higher displacement output, lower power consumption and heat generation, superior anti-depolarization performance, and smarter integration (e.g., with built-in sensors).

We firmly believe that exceptional core components are the cornerstone of building exceptional systems. We are not merely a supplier of piezoelectric ceramic elements but a trusted partner for robot designers and engineers. We are committed to empowering your innovative designs with our advanced multilayer stack piezoelectric ceramic solutions. Together, let's push the limits of robotic perception and execution, driving precision automation toward a smarter, more sensitive, and more reliable new era.

Explore how multilayer stack piezoelectric ceramics can inject precise power into your robotic projects. We welcome you to contact us anytime.