Multilayer Stack Piezoelectric Ceramics: The Core Driver Enhancing the Precision of Automated Equipment

In the wave of modern industrial automation, precision is often the key determinant of equipment performance and competitiveness. Whether in precision assembly, micro-nano machining, high-speed positioning, or vibration suppression, every micron of displacement and every millisecond of response directly impacts production efficiency and product quality. Against this backdrop, multilayer stack piezoelectric ceramic technology, with its exceptional performance, is quietly becoming a core component propelling automated equipment toward higher precision and faster response.

I. The Precision Challenge: The "Micron-Level" Pursuit of Automated Equipment

With the rapid development of high-end fields like smart manufacturing, semiconductor packaging, and biomedical devices, traditional mechanical transmission or electromagnetic drive methods are increasingly revealing limitations—issues such as backlash, response lag, and friction loss make it difficult to meet motion control requirements at the micron or even nanometer scale. Automated equipment calls for a technological solution capable of high-frequency, high-precision, direct drive. This is precisely where multilayer stack piezoelectric ceramics come into play.

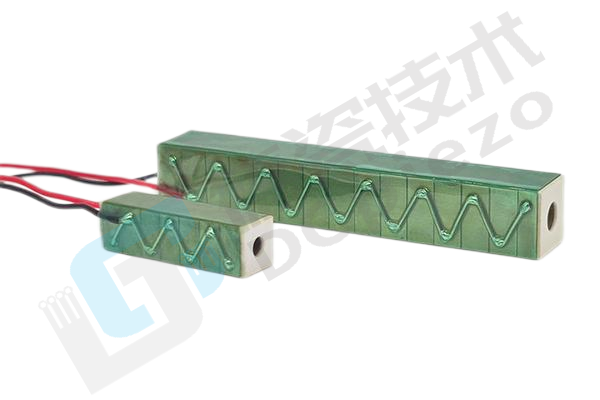

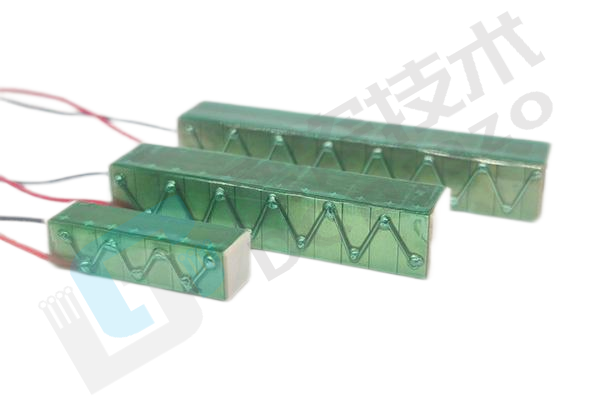

II. What Are Multilayer Stack Piezoelectric Ceramics?

Simply put, they are monolithic ceramic actuators fabricated through a special co-firing process that alternately stacks dozens or even hundreds of extremely thin piezoelectric ceramic layers with internal electrodes, based on the piezoelectric effect. When voltage is applied, each ceramic layer produces a minute deformation. These micro-deformations accumulate and superimpose along the stacking direction, resulting in a significantly larger overall displacement output compared to single-layer piezoelectric ceramics, while maintaining extremely high response speed and output force. Their structure resembles a "layer cake," with each layer contributing synergistically, ultimately unleashing energy far exceeding the sum of its parts.

III. Why Can It Significantly Enhance Equipment Precision?

1.Ultra-High Resolution & Positioning Accuracy: The multilayer stack design enables sub-nanometer resolution. Displacement has a highly linear relationship with input voltage. Combined with precise control systems, it allows for extremely accurate positioning and motion trajectory control, completely eliminating backlash and stick-slip phenomena common in traditional transmission systems.

2.Millisecond-Level Response Speed: The piezoelectric effect is inherently a rapid response to an electric field, typically completing expansion/contraction within milliseconds or even microseconds. This enables equipment to perform high-frequency reciprocating motion (up to thousands of Hertz), suitable for applications requiring rapid start-stop, real-time tracking, or active vibration compensation, greatly enhancing dynamic performance.

3.High Force Density: Despite their compact size, the multilayer stack structure allows them to generate thrust ranging from hundreds to thousands of Newtons, with a force density far surpassing most electromagnetic actuators. This enables them to drive delicate structures as well as handle precision tasks requiring substantial load, such as precise pressing or valve control.

4.High Stiffness & No Wear: As solid-state actuators, they contain no traditional moving parts during operation, eliminating mechanical friction and wear. This results in maintenance-free operation and long service life. High stiffness also implies strong resistance to interference and excellent system stability.

5.High Energy Efficiency: They consume electrical energy primarily during state changes, with almost no power consumption in static holding states, aligning with the modern industrial principles of energy conservation and environmental protection.

IV. Vivid Application Scenarios in Automated Equipment

● Precision Positioning Stages: Nano-positioning stages used in lithography machines, scanning electron microscopes, and chip bonders are the unsung heroes achieving "super precision." Multi-axis stack ceramic-driven stages enable complex multi-dimensional micro-adjustments.

● Active Vibration Damping & Isolation Systems: Environmental vibration is a major adversary in precision measurement and micro-machining. Active actuators based on multilayer stack piezoelectric ceramics can sense vibrations in real-time and generate counteracting forces to neutralize them, creating a "quiet" working environment for equipment.

● High-Speed Valves & Fluid Control: In micro-dispensing, fuel injection, and analytical instruments, piezoelectric ceramic valves control minute droplets or gas flows with extremely high frequency and precision, achieving flow control down to the picoliter level.

● Micro-Gripping & Force Feedback: In automated assembly and cell manipulation, piezoelectric ceramic micro-grippers enable gentle and precise grasping with sensitive force feedback, preventing damage to delicate components or biological samples.

● Ultrasonic Motors & Linear Drives: Utilizing the ultrasonic vibration of piezoelectric ceramics to drive rotors or sliders enables non-magnetic, silent, direct drives with high holding torque, widely used in optical focusing, precision slides, and other fields.

V. Key Considerations for Selection and Use

To fully realize the potential of multilayer stack piezoelectric ceramics, attention must be paid to the following:

● Driver Power Supply Matching: They require dedicated amplifiers providing high voltage (typically tens to hundreds of volts), low noise, and fast response.

● Displacement Sensing & Closed-Loop Control: For optimal precision and linearity, integrating strain sensors or capacitive displacement sensors to form a closed-loop control system is often necessary.

● Preload & Installation: Appropriate mechanical preload optimizes their force output and lifespan. Professional design of the mounting structure is crucial.

● Thermal Management: Operation under high-frequency driving generates some heat. Effective heat dissipation design ensures stable performance and long-term reliability.

VI. Toward a More Precise and Intelligent Future

On the path of automated equipment development toward greater precision, speed, and intelligence, multilayer stack piezoelectric ceramics are no longer merely simple components. They have become core power units enabling equipment to achieve extreme performance. With their silent yet powerful "internal force," they break through the limits of mechanical transmission, opening the door to the world of micro-nano manipulation for modern industry.

As a professional manufacturer deeply rooted in the field of piezoelectric ceramics, Deci Technology is committed to providing high-performance, high-reliability multilayer stack piezoelectric ceramic products and customized solutions. We believe that through close collaboration with automation equipment integrators, this sophisticated technology will empower more high-end equipment, jointly shaping a new era of smarter manufacturing characterized by greater precision and efficiency.