Precision Engineering · Intelligent Future | DeciTech High-Precision Surface Grinder Empowers Piezoelectric Ceramics Manufacturing

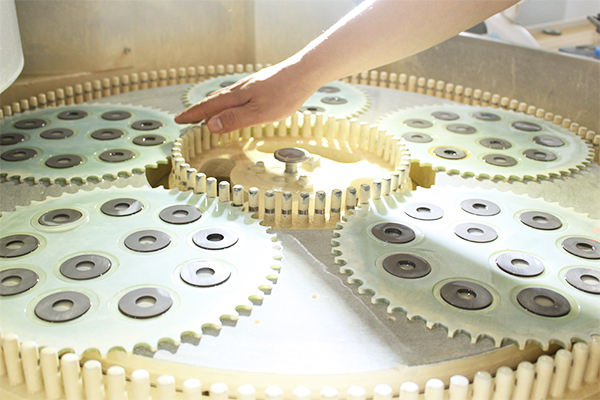

As a professional manufacturer of piezoelectric ceramic core components, DeciTech introduces high-end precision surface grinders with ±0.001mm machining accuracy and an intelligent control system, delivering nanometer-level planar grinding solutions for piezoelectric ceramic substrates, transducers, and other components.

The system ensures surface flatness ≤0.2μm and dimensional tolerances consistently controlled within ±0.005mm, laying a precision foundation for optimized piezoelectric performance output.

such as power grinding, so as to ensure the high quality and consistency of products.

Core Value of Equipment - Precision Grinding Technology Empowers Performance Leap

Ultra-Precision Surface Processing System

● High-Rigidity Imported Grinding Head + Diamond Wheel Set: Achieves 0.001mm-level feed accuracy

● Thermal Control Compensation System: Real-time correction of thermal deformation errors to ensure full-cycle machining stability

● Intelligent Online Inspection Module: Automatically identifies workpiece deformation and dynamically adjusts grinding parameters

Smart CNC Machining Platform

● 7-Axis CNC System: Supports complex curved surface programming and machining

● AI Process Database: Auto-matches piezoelectric ceramic material characteristic parameters

● HMI with Multi-Dimensional Monitoring: Integrates pressure/temperature/vibration monitoring, enabling 0.5-second emergency stop for abnormal conditions

High-Efficiency Flexible Production System

● Vacuum Adsorption + Robotic Auto-Loading: 300% increase in single-shift production capacity

● Modular Design: Compatible with Φ5-300mm multi-spec ceramic substrate processing

● Energy Optimization System: 40% less energy consumption than traditional equipment, 95% grinding fluid recycling rate