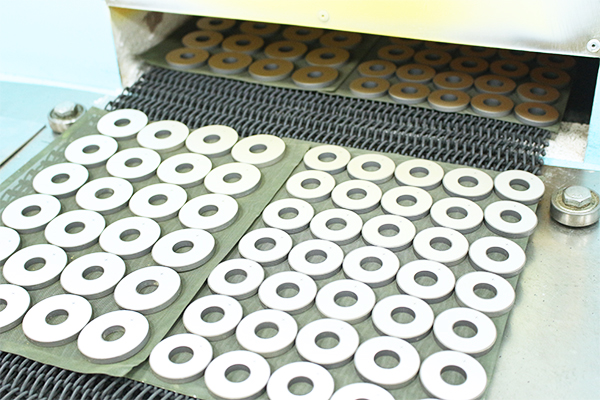

Precision Sintering · Silver-Driven Future | DeciTech Tunnel Silver-Firing Equipment Crafts High-Reliability Electrodes

As a professional manufacturer of piezoelectric ceramic core components, DeciTech's tunnel silver-firing equipment is specifically engineered for silver layer densification and Ohmic contact optimization. Equipped with infrared radiation heating and multi-zone temperature coordination technology, it supports diverse products including piezoelectric ceramic sheets, transducers, and buzzers, achieving:

30%+ improvement in silver layer conductivity

Electrode adhesion strength meeting industry-leading standards

Core Value of Equipment - Injecting Potency into Electrode Performance

High-Efficiency Precision Sintering System

● Infrared Radiation + Hot Air Circulation Dual-mode Heating: Temperature control accuracy of ±1.5℃

● 6-8 Independent Temperature Zones: Matches full-cycle silver paste processing (solvent volatilization-sintering-cooling)

● Stepless Speed Adjustment (0.5-3m/min): Daily processing capacity reaches 500kg

Intelligent Process Assurance System

● OPC-UA Protocol Integration with MES: Real-time sintering curve parameter recording

● Nitrogen Atmosphere Protection Module (Optional): Reduces silver layer oxidation risks

● Automatic Web Break/Deviation Correction: Yield rate increased to 99.6%

Energy-Saving Lean Design

● Waste Heat Recovery System: 40% energy consumption reduction

● Modular Structure: Enables rapid model changeover (<30min)

● Multi-point Emergency Cooling Channels: Ensures process safety redundancy with d33 value fluctuation range ≤3%, empowering high-end sensor and transducer manufacturing