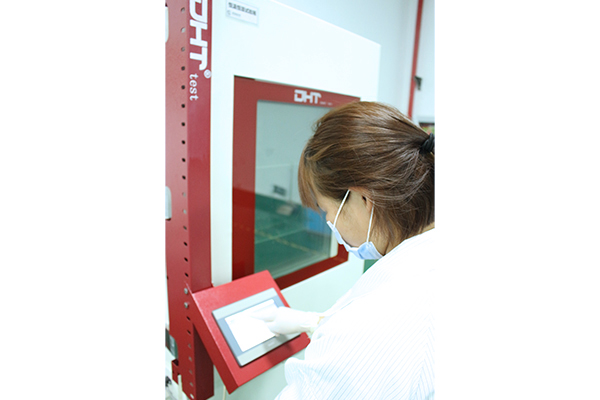

Precision Intelligence · Testing Frontier | DeciTech Lifecycle Test Chamber Safeguards Long-Term Performance of Piezoelectric Ceramics

As a professional manufacturer of piezoelectric ceramic core components, DeciTech's lifecycle test chamber delivers high-precision environmental simulation and intelligent data tracking, providing full-cycle testing assurance for validating the durability and stability of piezoelectric ceramic components.

Core Value of Equipment - Scientific Support for Long-term Reliability

Full-scenario Environmental Simulation: Precision Replication of Extreme Conditions

● -40℃ to 150℃ wide temperature cycling + 10%-95%RH adjustable humidity: Simulates harsh environments (thermal shock, damp heat aging, etc.).

● Customizable vibration frequency loading (0-2000Hz): Synchronizes with real-world piezoelectric ceramic operating conditions to accelerate life testing.

Multi-parameter Real-time Monitoring: Data-driven Quality Optimization

● Built-in high-precision sensors: Monitor core parameters (voltage, current, deformation, resonant frequency) with ±0.5% accuracy.

● Cloud-based data storage & analysis: Automatically generates aging curves and failure threshold reports for quantifiable design improvements.

Intelligent Safety Protection: Ensuring Efficient Test Operations

● Dual-circuit overload protection + power-loss data auto-backup: Zero data loss in prolonged testing.

● Modular chamber design: Enables parallel multi-batch testing with 40% efficiency improvement and 15% energy consumption reduction.