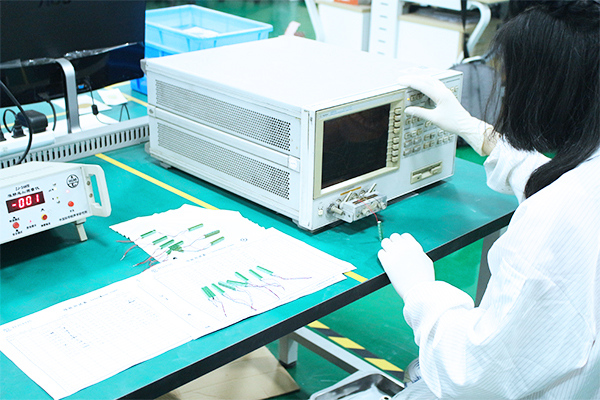

Precision Testing · Intelligent Control | DeciTech Fully Automated Electrical Testing System Safeguards Piezoelectric Ceramic Performance Benchmarks

As a professional manufacturer of piezoelectric ceramic core components, DeciTech's self-developed fully automated electrical testing system delivers microvolt-level accuracy, multi-parameter simultaneous detection, and intelligent data management, providing a one-stop testing solution for critical parameters including dielectric constant, piezoelectric coefficients, and electromechanical coupling coefficients, empowering zero-defect delivery of product performance.

Core Value of Equipment - Precise Quantification of Piezoelectric Performance

High-Precision Testing Capability

● ±0.5% measurement accuracy: Covers piezoelectric coefficients (d33/d31/d15) from 1pC/N to 650pC/N and dielectric properties at 1kHz~10MHz frequencies.

● Four-terminal shielding technique: Effectively eliminates electromagnetic interference for stable microcurrent signal acquisition.

Multi-parameter Integrated Testing

● Single-unit integration: Simultaneously analyzes 12 core parameters including resonant/anti-resonant frequencies, mechanical quality factor (Qm), impedance characteristics, and loss tangent (tanδ).

● Customizable electrode contact modules: Compatible with non-destructive testing of ring-shaped, sheet-type, and irregular ceramics.

AI-powered Intelligent Management

● SPC data dashboard: Generates real-time CPK process capability analysis reports and auto-determines batch qualification rates.

● QR code binding for test data: Enables full lifecycle traceability of production batches.

Industrial-grade Reliability Design

● Military-grade shielded chamber + constant temperature/humidity testing environment: Ensures 24/7 annual operational stability.

● Modular structural design: Hot-swappable key sensors improve maintenance efficiency by 60%.