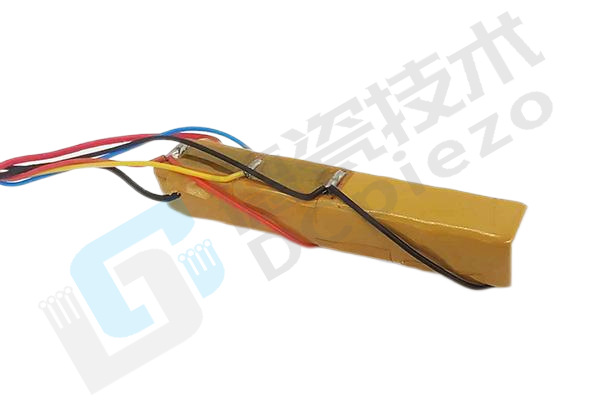

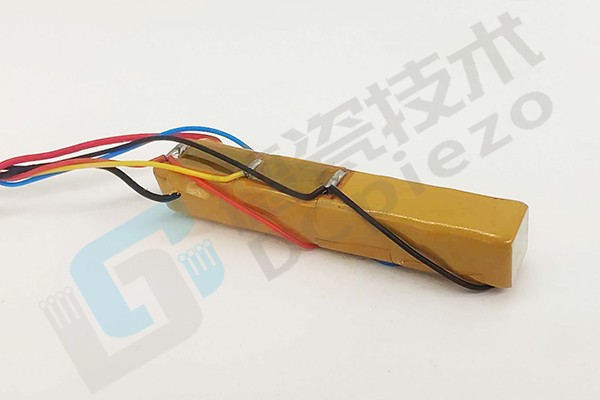

Closed-Loop Multi-Layer Stack Piezoelectric Ceramic

A high-precision piezoelectric actuator with integrated strain feedback, employing a Wheatstone bridge sensing system to monitor and compensate displacement deviations and hysteresis in real time, achieving sub-micron closed-loop control. Its multi-layer stacked piezoelectric structure, combined with precision strain gauge layout and temperature compensation, significantly enhances displacement linearity and long-term stability. Designed for precision positioning, active vibration suppression, and micro-force control, it serves semiconductor manufacturing, optical instruments, medical devices, and aerospace applications, delivering precise actuation for complex dynamic systems.

Closed-Loop Multi-Layer Stack Piezoelectric Ceramic

Closed-Loop Multi-Layer Stack Piezoelectric Ceramic

Breaking traditional open-loop limitations through "actuation + sensing" integration, this component provides reliable technical assurance for high-precision dynamic control. As specialized manufacturers, we fuse material innovation with closed-loop processes to empower semiconductor, optical, and medical industries with upgraded performance and efficiency.

Structural Design

● Closed-Loop Sensing Architecture: Four foil strain gauges arranged in a Wheatstone bridge on the ceramic surface, with active/passive gauge pairs for displacement feedback and 90%+ temperature interference suppression.

● Multi-Layer Stacking: Co-fired (PZT/electrode layers sintered as a monolith) or discrete stacking (epoxy-bonded individual layers) options – the former for high mechanical strength, the latter for extended displacement.

● Full Encapsulation: Epoxy-coated stack and strain gauges with moisture/shock resistance, low-noise signal leads for stable performance.

Material Properties

● High-Performance PZT: Lead zirconate titanate (PZT) ceramics with d33≥550 pC/N and <5% hysteresis post-polarization.

● Low-Noise Electrodes: Ag-Pd alloy internal electrodes and Ag-printed external electrodes (resistivity <0.2Ω·cm) for kHz-level driving.

● High-Sensitivity Strain Gauges: Active gauges with sensitivity ≥2.0, passive gauges with >90% thermal drift compensation, achieving >99.5% bridge linearity.

Core Advantages

● Real-Time Closed-Loop Control: >95% displacement error compensation and 0.1%FS linearity via strain feedback.

● Hysteresis/Thermal Suppression: Dual-gauge differential design reduces hysteresis to <1.5% and improves long-term stability by 3X.

● Broad Dynamic Range: <50μs response time for precise control across 0.1Hz~5kHz.

● Robust Packaging: Shock/moisture-resistant, operable at -25°C~130°C with >1×10⁸ cycle life.

Typical Applications

● Semiconductor: Lithography mask stage nano-positioning, wafer probe station micro-force control.

● Precision Optics: Adaptive mirror real-time correction, laser interferometer dynamic tuning.

● Medical Devices: Surgical robot haptic force control, endoscopic anti-shake actuation.

● Industrial Automation: CNC machine vibration damping, robotic arm trajectory correction.

● Aerospace: Satellite optical payload fine-tuning, aircraft active noise cancellation.

Quality Commitment

● Full-Process QC: Laser-monitored layer thickness and strain gauge sensitivity from powder synthesis to integration, 100% closed-loop validation.

● Customization: Tailored displacement, driving voltage, bridge excitation (≤4.5Vrms), and closed-loop algorithm adaptation.

● Lifecycle Support: System modeling, signal conditioning design, maintenance guidance, failure analysis, and 24/7 technical response.