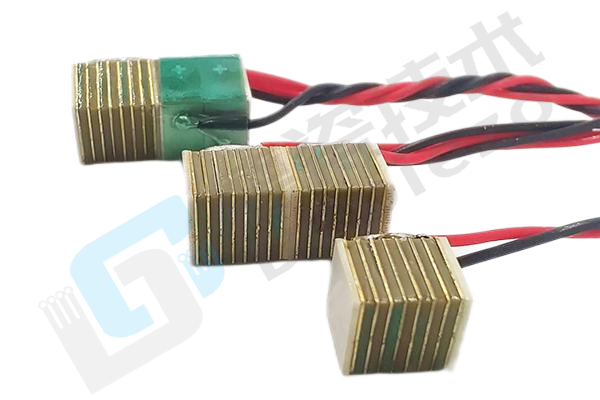

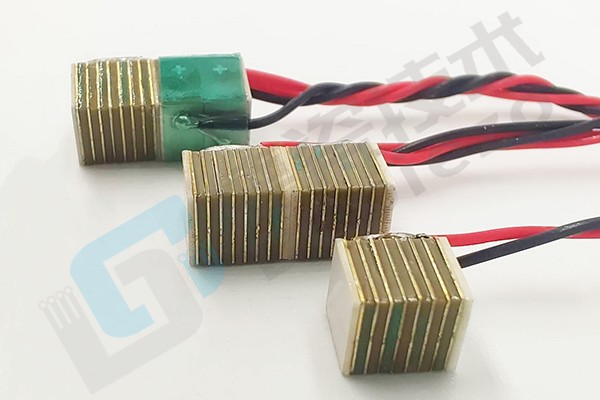

Multi-Layer Stack Piezoelectric Shear Element

A high-performance piezoelectric ceramic component operating in shear mode, combining multi-layer stacking architecture with shear-direction polarization to deliver large shear displacement and high lateral force output. This innovative design overcomes traditional piezoelectric ceramics' longitudinal deformation limitations, generating shear forces perpendicular to the stacking direction within compact dimensions. Ideal for high-frequency vibration suppression, precision micro-adjustment, and dynamic sensing, it is widely used in precision instruments, acoustic devices, robotic haptic feedback, and industrial automation, enabling efficient energy conversion and precise control in complex mechanical environments.

Multi-Layer Stack Piezoelectric Shear Element

Multi-Layer Stack Piezoelectric Shear Element

Redefining lateral precision actuation and dynamic control through shear-mode innovation and multi-layer stacking technology. As specialized piezoelectric manufacturers, we address shear application challenges via material breakthroughs and refined processes, delivering high-reliability, rapid-response customized solutions to elevate high-end equipment performance.

Structural Design

● Shear-Mode Stack Architecture: Multi-layer ceramics stacked along shear direction with orthogonal polarization/field orientation, directly converting electrical excitation into transverse shear deformation for amplified displacement and force.

● Interdigitated Electrodes: Alternating electrodes on ceramic layers optimize electric field distribution, ensuring uniform shear force output and eliminating stress-induced performance degradation.

● Compact Encapsulation: High-strength insulated housing with preload adjustment mechanism enhances shear impact resistance, supporting high-frequency/high-load operations.

Material Properties

● High-Shear Piezoelectric Material: Modified PZT-based composition tailored for shear mode, achieving exceptional shear piezoelectric constant (d15≥800 pC/N) with 30%+ energy conversion efficiency.

● Fatigue Resistance: Grain boundary engineering minimizes internal friction, enabling >10^7 high-frequency shear cycles with <5% performance degradation.

● Broad Thermal Stability: Operational range of -25°C~130°C with thermal drift coefficient <0.05%/°C, ensuring stable output in harsh environments.

Core Advantages

● High Shear Displacement: Delivers tens of microns of shear travel with 2-3X higher force density than conventional ceramics, meeting heavy-load micro-adjustment demands.

● Ultra-Fast Dynamics: Microsecond-level electromechanical response supports kHz-range driving for real-time vibration damping and dynamic compensation.

● Anti-Interference Capability: Decoupled shear/axial force output minimizes external vibration impact on system accuracy.

● Extended Lifespan: Adhesive-free full-sintering process prevents layer separation, achieving >1×10^8 cycles under continuous high-frequency use.

Typical Applications

● Precision Instruments: SEM stage micro-positioning, AFM probe actuation.

● Acoustic Systems: Ultrasonic transducer arrays, active noise-cancelling speaker vibration control.

● Industrial Automation: Tactile feedback for robotic assembly arms, anti-shake platforms in semiconductor packaging.

● Robotics: Biomimetic joint actuation, force-sensitive end-effectors.

● Automotive Electronics: Vibration compensation for automotive radars, active engine damping systems.

Quality Assurance

● Full-Process Control: Strict polarization uniformity and electrode alignment checks from material formulation to assembly, 100% shear force testing and fatigue validation.

● Customization Expertise: Tailored shear displacement, force, voltage, and frequency specifications with driver circuit co-design services.

● Application Engineering: Scenario simulation, integration guidance, and fault diagnosis to maximize performance and accelerate deployment.