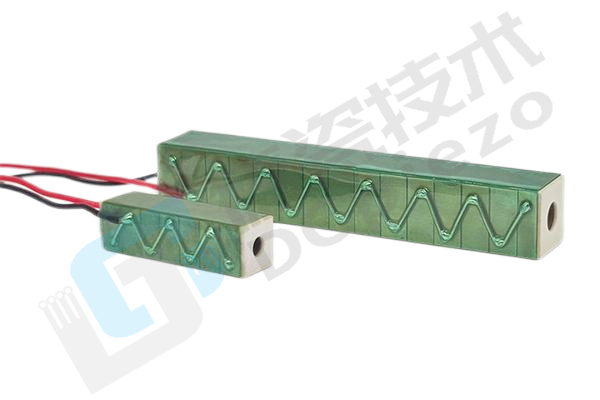

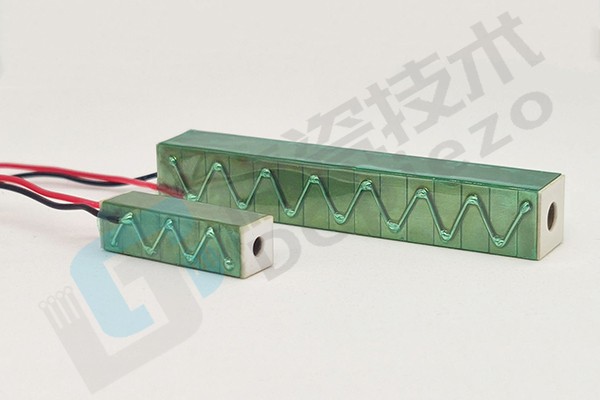

Square Central-Bore Multi-Layer Stack Piezoelectric Ceramic

A high-performance piezoelectric component specifically engineered for integrated system demands. Building upon the square multi-layer stack architecture, it introduces an innovative central through-hole design that combines precision actuation with multi-functional integration. Its multi-layer ultra-thin piezoelectric ceramic stacking and precise electrode configuration deliver high force output and sub-nanometer displacement control, while the central bore provides dedicated space for optical paths, fluid channels, or cable routing – significantly simplifying complex system layouts. Ideal for optical alignment, microfluidics control, endoscopic device actuation, and other advanced applications requiring synchronized mechanical motion and media transmission.

Square Central-Bore Multi-Layer Stack Piezoelectric Ceramic

Square Central-Bore Multi-Layer Stack Piezoelectric Ceramic

Redefining functional boundaries of traditional piezoelectric components through dual-functional "actuation + channel" integration, offering novel solutions for miniaturization and system innovation. As specialized manufacturers, we refine central-bore stacking processes with rigorous performance control, delivering irreplaceable piezoelectric solutions for highly integrated precision systems.

Structural Design

● Integrated Central-Bore Stacking: Customizable central through-hole (diameter adjustable) preserves high force output and precision of multi-layer ceramics while providing robust mechanical support without compromising structural integrity.

● Symmetry-Optimized Configuration: Square cross-section with radially symmetric electrode layout minimizes stress concentration under eccentric loads, ensuring torsional stability and durability during high-frequency operation.

● Modular Encapsulation: Moisture-resistant and shock-absorbent packaging materials with optional bore wall treatments (insulation coating/metallization) to accommodate optical, fluidic, or electrical interface requirements.

Material Properties

● High-Stability Piezoelectric Material: Modified PZT-based composition enhanced by gradient sintering technology ensures uniform electromechanical performance (d33≥580 pC/N) with optimized density at bore edges.

● Thermal Shock Resistance: Matched thermal expansion coefficients and bore-enhanced heat dissipation enable stable operation across -25°C~130°C.

● Ultra-Low Dielectric Loss: Minimal internal defects achieve dielectric loss <1.2%, supporting high-frequency pulse-driven applications with reduced energy dissipation.

Core Advantages

● Dual-Function Integration: Seamlessly combines actuation and media channels to eliminate external connectors, reducing system complexity and footprint.

● Precision-Power Synergy: Delivers hundreds of Newtons of thrust within micron-level strokes and 0.1-nm displacement resolution, maintaining axial stiffness despite central bore.

● Superior Dynamics: <50μs electromechanical response time enables kHz-level vibration control, with bore structure suppressing resonance peaks for extended operational bandwidth.

● Extended Service Life: Adhesive-free full-sintering process prevents delamination, coupled with bore-edge stress optimization for >5×10^7 cycle durability.

Typical Applications

● Optical Alignment: Laser beam centering calibration, fiber-optic docking drives (optical signal transmission through bore).

● Microfluidics Control: Integrated valve actuation and fluid channels in lab-on-chip devices, precision droplet dispensing in bioassays.

● Medical Instruments: Endoscopic multi-DOF bending joints (bore for cabling/biopsy channels), compact ultrasound imaging probes.

● Industrial Systems: High-frequency vibration energy harvesters, multi-axis piezoelectric actuators (bore routing to minimize EMI).

Quality Commitment

● Full-Process Control: Automated inspection from tape casting to bore machining, ensuring ±5μm bore tolerance and <0.5% layer alignment deviation.

● Customization Expertise: Flexible central bore dimensions, electrode configurations, and encapsulation formats, supported by cross-disciplinary actuation-mechanical-fluidic co-design.

● Lifecycle Support: Closed-loop technical services including simulation modeling, application-specific testing, failure analysis, and 24/7 customer response.