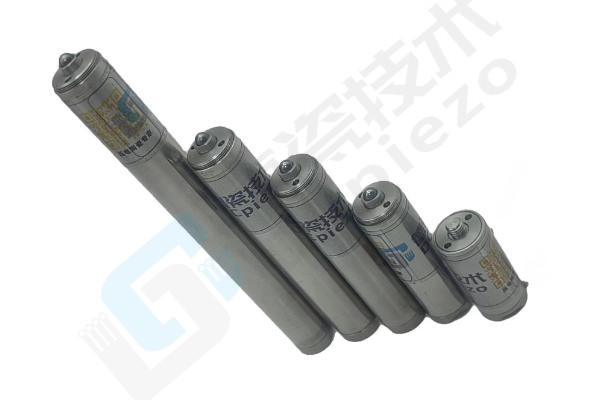

Piezoelectric Actuator / DCSA3-R15 Series

A high-precision actuator based on multi-layer piezoelectric ceramic stacking technology, designed for micro/nano-scale displacement control and high-force applications. This compact 15mm-diameter series integrates piezoelectric ceramic stacks with a flexure hinge support system, delivering micron-to-nanometer displacement and kilonewton-level thrust via voltage modulation. Featuring coaxial shielded wiring, customizable end caps, and fixed bases, it is widely used in precision positioning, vibration suppression, and fluid control for optical, semiconductor, and medical equipment.

DCSA3-R15 Series Piezoelectric Actuator

DCSA3-R15 Series Piezoelectric Actuator

Redefining micro-actuation performance with ultra-precision, high force, and robust environmental adaptability. As specialized piezoelectric manufacturers, we deliver reliable, rapid-response customized solutions through material innovation and precision engineering, driving technological advancements in optics, semiconductors, and medical fields.

Structural Design

● Piezoelectric Stack Core: Multi-layer ceramic stacks integrated with flexure hinges to convert piezoelectric deformation into controlled axial linear displacement (extension/contraction).

● Modular Encapsulation: Stainless steel/titanium housing with preload mechanisms ensures uniform stress distribution, preventing delamination under kHz-level dynamic operations.

● Custom Interfaces: Tailorable end caps, bases, and connectors with coaxial shielded wiring to minimize EMI and enhance signal integrity.

Material Properties

● High-Performance PZT: Modified lead zirconate titanate (PZT)-based material with d33≥600 pC/N, hysteresis <3%, and thermal drift <0.02%/°C for superior electromechanical efficiency.

● Fatigue-Resistant Flexures: Titanium alloy hinges with 0.02N/μm stiffness, >50G shock resistance, and >1×10⁸ cycles in -25°C~130°C environments.

● Low-Loss Electrodes: Ag-Pd alloy electrodes with coaxial shielding (resistivity <0.1Ω·cm) support high-frequency driving with controlled thermal rise.

Core Advantages

● Nanometer-Level Resolution: 0.1nm displacement resolution and <0.15%F.S. repeatability for ultra-precision optical tuning and micromachining.

● High Force Density: Kilonewton-level thrust output with superior stiffness and force density vs. traditional electromagnetic actuators.

● Rapid Dynamics: 80ms full-step response and >125Hz resonance frequency for real-time vibration control and dynamic compensation.

● Environmental Versatility: Optional vacuum-rated versions for stable operation in oil, humidity, or vacuum environments.

Typical Applications

● Precision Optics: Laser resonator dynamic tuning, Fiber Bragg Grating (FBG) deformation control, adaptive optics wavefront correction.

● Semiconductor Manufacturing: Wafer probe station force feedback, lithography mask nano-positioning.

● Medical Devices: Endoscopic precision actuation, microsurgical robot haptic feedback.

● Industrial Automation: CNC machine vibration damping, microfluidic valve high-frequency control.

● Research Instruments: Atomic force microscope probe actuation, cryogenic displacement compensation.

Quality Commitment

● Full-Process QC: Laser-verified displacement linearity and force consistency from lamination to assembly, 100% thermal cycling and fatigue testing.

● Customization: Tailored displacement ranges, driving voltages, interfaces (threaded/flange), and protection levels with open/closed-loop configurations.

● Lifecycle Support: Dynamic simulation, driver circuit matching, installation stress analysis, failure diagnostics, and 24/7 customization response.