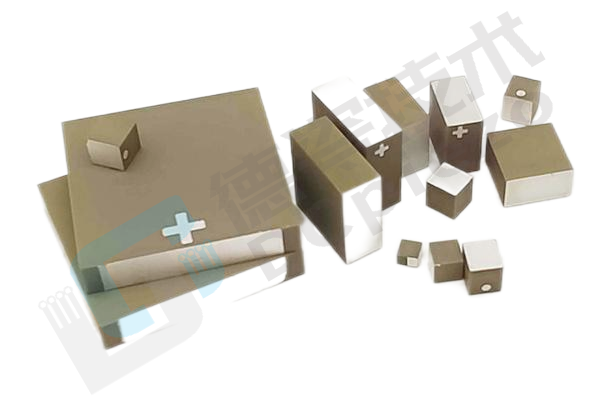

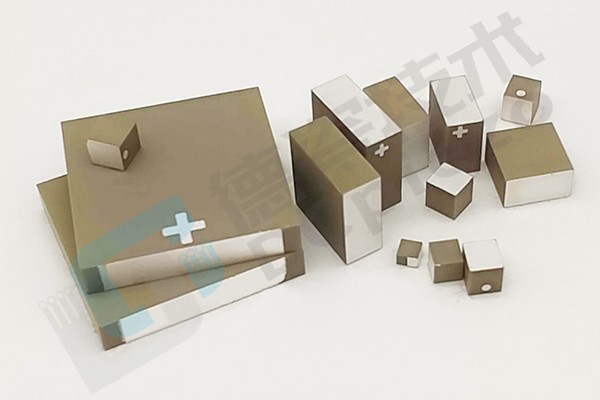

Square Piezoelectric Ceramic Chip

A high-performance multi-layer stacked piezoelectric core component designed for compact precision actuation and sensing. Featuring alternating ceramic and electrode layers, it enables low-voltage driving, rapid response, and high-accuracy displacement output. The chip integrates dozens to hundreds of ultra-thin piezoelectric layers with printed external electrodes and full-ceramic insulation on all sides, omitting a central bore to maximize structural integrity. Widely used in optical focusing, ultrasonic transduction, MEMS, and automation control, it delivers miniaturized, highly reliable electromechanical conversion for space-constrained applications.

Square Piezoelectric Ceramic Chip

Square Piezoelectric Ceramic Chip

Achieving optimal balance between low-voltage operation and precision control through multi-layer stacking innovation. As specialized manufacturers, we provide high-reliability, rapid-response core components via advanced materials and precision engineering, empowering breakthroughs in optical, ultrasonic, and automation technologies.

Structural Design

● Multi-Layer Cross Stacking: Ultra-thin piezoelectric ceramic layers alternating with internal electrodes, featuring printed external electrodes on both sides. Customizable stack thickness (standard: 2mm/3mm) with 0.1% thickness-to-displacement ratio and >99% linearity.

● Full-Seal Insulation: Dense ceramic insulation on all sides for moisture/leakage protection, with crosshair polarity markers to prevent installation errors.

● Bore-Free Compact Design: Solid structure enhances mechanical strength for high-load scenarios, supporting surface mounting or mechanical preload fixation.

● Interface Flexibility: Available as bare chips or pre-bonded with wires (Au/Cu) for soldering/spring-contact integration.

Material Properties

● High-Activity Piezoelectric Ceramic: Modified PZT-based material with d33≥500 pC/N and enhanced electromechanical coupling, improving energy efficiency by 40%+.

● Low-Impedance Electrodes: Ag-Pd alloy internal electrodes and Ag-printed external electrodes (resistivity <0.3Ω·cm) support wide voltage ranges (-30V~150V) and kHz-level responses.

● Precision Machining: Surface flatness <±5μm and roughness Ra<0.2μm ensure optimal contact and minimal energy loss.

Core Advantages

● Low-Voltage High-Output: Operates at reduced voltages (-10V~75V/-20V~100V/-30V~150V) with 150N/mm² force density, ideal for portable/low-power systems.

● Sub-Micron Precision: Nanometer-level resolution and <0.1% repeatability for ultra-precise positioning and micro-force control.

● Microsecond Response: <50μs electromechanical response enables high-frequency dynamics (ultrasonic vibration, fast valving).

● Environmental Robustness: Full-ceramic encapsulation withstands moisture/aging, operable at -25°C~130°C with >5×10^7 cycle life.

Typical Applications

● Optical Systems: Microscope objective focusing, laser cavity real-time length correction.

● Ultrasonic Tech: Ultrasonic cleaner transducers, NDT probes, medical imaging oscillators.

● Automation: Semiconductor bond head force feedback, robotic joint actuation.

● MEMS: Micro-sensor excitation, micropump diaphragm drives.

● Consumer Electronics: Smartphone camera OIS modules, haptic feedback units.

Quality Commitment

● Full-Process QC: Laser-monitored thickness/flatness from tape casting to sintering, 100% high-voltage polarization and displacement validation.

● Customization: Tailored thickness (1-10mm), voltage ranges, force/displacement curves, and wire bonding options, with prototypes in 7 business days.

● Technical Support: Driver circuit matching, installation stress simulation, dynamic optimization, and 24/7 consultation.