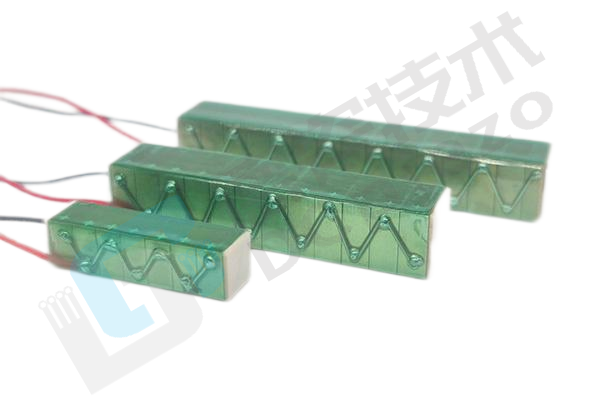

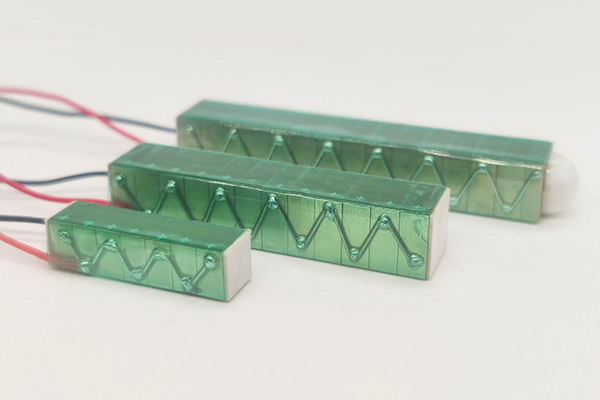

Square Multi-Layer Stack Piezoelectric Ceramic

Square Multi-Layer Stack Piezoelectric Ceramic

Redefining the boundaries of precision actuation and sensing technology through innovative structural design, superior material properties, and rigorous manufacturing standards. As a professional piezoelectric ceramic manufacturer, we empower clients via full-process technological integration, delivering highly reliable and high-performance customized solutions to advance cutting-edge applications.

Structural Design

● Multi-Layer Stack Architecture: Dozens to hundreds of ultra-thin piezoelectric ceramic layers are stacked with alternating internal electrode polarization, significantly enhancing axial displacement and force output while maintaining compact dimensions.

● Square-Optimized Structure: Square cross-section design improves mechanical stability for parallel grouping or array configurations. Symmetrical structure reduces thermal stress while enhancing heat dissipation and long-term reliability.

● Precision Encapsulation: High-temperature-resistant insulation materials with built-in preload adjustment ensure uniform stress distribution across layers, preventing delamination and supporting high-frequency dynamic operations.

Material Properties

● High-Performance Piezoelectric Ceramic: Modified lead zirconate titanate (PZT)-based materials with high Curie temperature, exceptional piezoelectric constant (d33≥600 pC/N), and superior electromechanical coupling coefficients enable efficient energy conversion.

● Thermal Stability: Optimized doping and sintering processes ensure stable performance across a broad temperature range (-25°C to 130°C) with minimal drift, guaranteeing consistent output in harsh environments.

● Low Loss Characteristics: Low dielectric loss (tanδ<1.5%) and mechanical loss support kHz-level driving frequencies, reducing heat generation and extending operational lifespan.

Core Advantages

● High Force Density: Multi-layer structure generates hundreds of Newtons of thrust under low voltage (≤200V), far exceeding conventional single-layer ceramics.

● Sub-Nanometer Precision: Displacement resolution reaches sub-nanometer levels with repeatability <0.1%, meeting ultra-precision positioning demands.

● Millisecond Response: Electromechanical response time as low as microseconds, suitable for high-frequency dynamic adjustments and real-time feedback systems.

● Extended Lifespan: Full-density ceramic structure without adhesive layers ensures high fatigue resistance, cycle life >10^8, and 24/7 continuous operation.

Typical Applications

● Semiconductor Manufacturing: Mask stage micro-motion correction, wafer probe station precision alignment.

● Optical Instruments: Adaptive optics mirror actuation, laser beam stabilization, and focus control.

● Medical Devices: Ultrasonic scalpel transducers, endoscopic micro-drive modules.

● Industrial Automation: High-frequency valve control, active vibration suppression platforms.

● Aerospace: Satellite optical payload fine-tuning mechanisms, precision inertial navigation system compensators.

Quality Assurance

● Full-Process QC: Comprehensive quality management from powder synthesis to final testing, with 100% high-voltage polarization, aging tests, and laser displacement calibration.

● Customization: Tailored solutions for dimensions, force, displacement, impedance, and collaborative structural/driver circuit optimization.

● Lifetime Support: Simulation, installation guidance, application-specific solutions, failure analysis, and rapid response to customer needs.

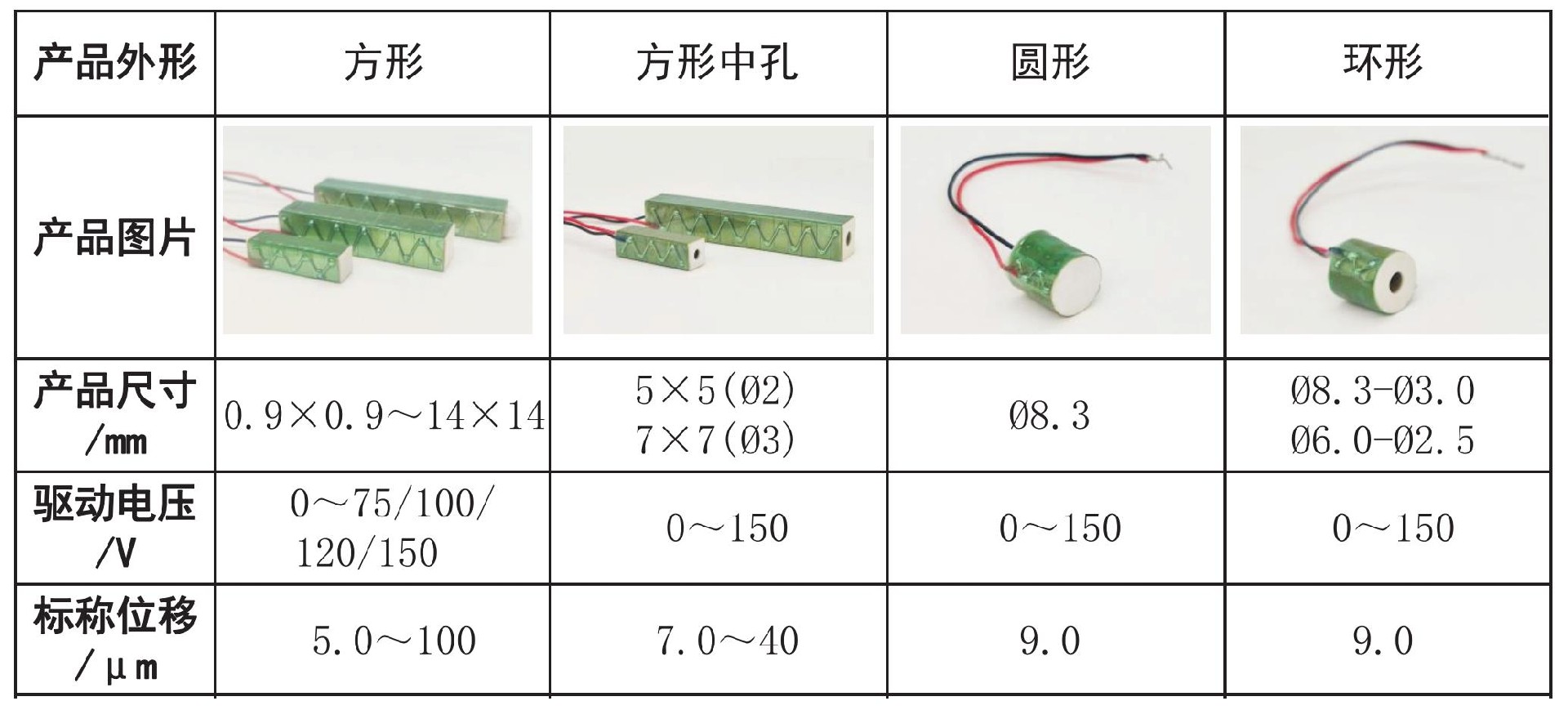

There are insulating ceramic layers on the side of the stack. Compared with the epoxy coating, the ceramic layer can isolate moisture better. 75mm long wires are pre installed in the stack and wrapped in Kapton ® In the tape. We can also customize the size, voltage range and coating of piezoelectric ceramic chip.

Two end faces of the piezoelectric ceramic stack are attached with ceramic end caps. Flat or hemispherical end caps are available. When the load is along the translation axis of the actuator, the planar end cap can achieve large force transmission because of its large contact area. The hemispherical end cap allows the actuator to engage the off-axis load because the surface moves the force along the translation axis of the actuator. The ceramic end cap not only helps to distribute the force applied by the load on the mounting surface of the stack, but also helps to guide the force along the moving axis of the driver.

square | Voltage | Product size | capacitance(±15%) | frequency | displacement(±15%) | Maximum thrust |

DCS1-030318 | 75 V | 3.0 × 3.0 × 18.8 mm | 2.25 µF | 65 kHz | 18.0 µm | 360 N |

DCS1-030331 | 75 V | 3.0 × 3.0 × 31.0 mm | 3.75 µF | 40 kHz | 30.0 µm | 360 N |

DCS1-050510 | 75 V | 5.0 × 5.0 × 10.5 mm | 4.2 µF | 115 kHz | 11.2 µm | 1000 N |

DCS1-050518 | 75 V | 5.0 × 5.0 × 18.0 mm | 7.3 µF | 65 kHz | 19.6 µm | 1000 N |

DCS1-050523 | 75 V | 5.0 × 5.0 × 23.0 mm | 9.4 µF | 55 kHz | 25.2 µm | 1000 N |

DCS1-050539 | 75 V | 5.0 × 5.0 × 39.8 mm | 16.5 µF | 30 kHz | 44.8 µm | 1000 N |

DCS2-020210 | 100V | 2.0 × 2.0 × 10.9 mm | 240 nF | 115 kHz | 9.5 µm | 160 N |

DCS2-030310 | 100V | 3.0 × 3.0 × 10.9 mm | 620 nF | 115 kHz | 10.5 µm | 360 N |

DCS2-030320 | 100V | 3.0 × 3.0 × 20.9 mm | 1.25 µF | 60 kHz | 21.0 µm | 360 N |

DCS2-030331 | 100V | 3.0 × 3.0 × 31.0 mm | 1.85 µF | 40 kHz | 31.5 µm | 360 N |

DCS5-070736 | 120V | 7.0 × 7.0 × 36.0 mm | 7.2 µF | 35 kHz | 38.0 µm | 1960 N |

DCS3-020210 | 150V | 2.0 × 2.0 × 10.9 mm | 110 nF | 115 kHz | 9.5 µm | 160 N |

DCS3-252505 | 150V | 2.5 × 2.5 × 5.0 mm | 100 nF | 250 kHz | 5.2 µm | 250 N |

DCS3-252510 | 150V | 2.5 × 2.5 × 10.0 mm | 175 nF | 130 kHz | 9.2 µm | 250 N |

DCS3-252519 | 150V | 2.5 × 2.5 × 19.4 mm | 360 nF | 68 kHz | 19.0 µm | 250 N |

DCS3-030305 | 150V | 3.0 × 3.0 × 5.0 mm | 130 nF | 265 kHz | 4.8 µm | 360 N |

DCS3-030307 | 150V | 3.0 × 3.0 × 7.0 mm | 180 nF | 192 kHz | 6.8 µm | 360 N |

DCS3-030309 | 150V | 3.0 × 3.0 × 9.0 mm | 250 nF | 140 kHz | 9.5 µm | 360 N |

DCS3-030310 | 150V | 3.0 × 3.0 × 10.0 mm | 275 nF | 132 kHz | 11.0 µm | 360 N |

DCS3-030318 | 150V | 3.0 × 3.0 × 18.8 mm | 530 nF | 65 kHz | 19.8 µm | 360 N |

DCS3-030331 | 150V | 3.0 × 3.0 × 31.0 mm | 930 nF | 40 kHz | 33.0 µm | 360 N |

DCS3-050509 | 150V | 5.0 × 5.0 × 9.0 mm | 650 nF | 140 kHz | 9.5 µm | 1000 N |

DCS3-050510 | 150V | 5.0 × 5.0 × 10.0 mm | 800 nF | 126 kHz | 10.0 µm | 1000 N |

DCS3-050512 | 150V | 5.0 × 5.0 × 12.0 mm | 850nF | 105 kHz | 12.0µm | 1000 N |

DCS3-050518 | 150V | 5.0 × 5.0 × 18.0 mm | 1.5 µF | 70 kHz | 20.0 µm | 1000 N |

DCS3-050520 | 150V | 5.0 × 5.0 × 20.0mm | 1.6 µF | 65 kHz | 21.0 µm | 1000 N |

DCS3-050536 | 150V | 5.0 × 5.0 × 36.0 mm | 3.0 µF | 34 kHz | 40.0 µm | 1000 N |

DCS3-050538 | 150V | 5.0 × 5.0 × 38.0 mm | 3.3 µF | 34 kHz | 40.0 µm | 1000 N |

DCS3-050540 | 150V | 5.0 × 5.0 × 40.0 mm | 3.2µF | 32 kHz | 43.0 µm | 1000 N |

DCS3-050548 | 150V | 5.0 × 5.0 × 48.0 mm | 4.2 µF | 26 kHz | 50.0 µm | 1000 N |

DCS3-050550 | 150V | 5.0 × 5.0 × 50.0 mm | 4.1µF | 25 kHz | 55.0 µm | 1000 N |

DCS3-070709 | 150V | 7.0 × 7.0 × 9.0 mm | 1.4 µF | 130 kHz | 8.5 µm | 1960 N |

DCS3-070718 | 150V | 7.0 × 7.0 × 18.0 mm | 2.9 µF | 70 kHz | 19.0 µm | 1960 N |

DCS3-070720 | 150V | 7.0 × 7.0 × 20.0 mm | 3.2 µF | 62 kHz | 21.0 µm | 1960 N |

DCS3-070730 | 150V | 7.0 × 7.0 × 30.0 mm | 4.6 µF | 42 kHz | 32.0 µm | 1960 N |

DCS3-070736 | 150V | 7.0 × 7.0 × 36.0 mm | 6.0 µF | 35 kHz | 38.0 µm | 1960 N |

DCS3-070745 | 150V | 7.0 × 7.0 × 45.0 mm | 7.2 µF | 27 kHz | 50.0 µm | 1960 N |

DCS3-070750 | 150V | 7.0 × 7.0 × 50.0 mm | 8.5µF | 24 kHz | 55.0 µm | 1960 N |

DCS3-070790 | 150V | 7.0 × 7.0 × 90.0 mm | 15.5 µF | 14 kHz | 100.0 µm | 1960 N |

DCS3-101018 | 150V | 10.0 × 10.0 × 18.0 mm | 6.0 µF | 65 kHz | 20.0 µm | 4000 N |

DCS3-101036 | 150V | 10.0 × 10.0 × 36.0 mm | 13.0 µF | 34 kHz | 40.0 µm | 4000 N |

DCS3-101045 | 150V | 10.0 × 10.0 × 45.0 mm | 15.0 µF | 15 kHz | 50.0 µm | 4000 N |

DCS1-030332C1 | 75 V | 3.0 × 3.0 × 32.2 mm | 3.75 µF | 40 kHz | 30.0 µm | 360 N |

DCS1-050512C1 | 75 V | 5.0 × 5.0 × 12.6 mm | 4.2 µF | 115 kHz | 11.2 µm | 1000 N |

DCS1-050520C1 | 75 V | 5.0 × 5.0 × 20.1 mm | 7.3 µF | 65 kHz | 19.6 µm | 1000 N |

DCS1-050525C1 | 75 V | 5.0 × 5.0 × 25.1 mm | 9.4 µF | 55 kHz | 25.2 µm | 1000 N |

DCS1-050541C1 | 75 V | 5.0 × 5.0 × 41.9 mm | 16.5 µF | 30 kHz | 44.8 µm | 1000 N |

DCS2-020211C1 | 100V | 2.0 × 2.0 × 11.5 mm | 240 nF | 115 kHz | 9.5 µm | 160 N |

DCS2-030312C1 | 100V | 3.0 × 3.0 × 12.0 mm | 620 nF | 115 kHz | 10.5 µm | 360 N |

DCS2-030322C1 | 100V | 3.0 × 3.0 × 22.1 mm | 1250 nF | 60 kHz | 21.0 µm | 360 N |

DCS2-030332C1 | 100V | 3.0 × 3.0 × 32.2 mm | 1850 nF | 40 kHz | 31.5 µm | 360 N |

DCS3-020211C1 | 150V | 2.0 × 2.0 × 11.5 mm | 110 nF | 115 kHz | 9.5 µm | 160 N |

DCS3-252506C1 | 150V | 2.5 × 2.5 × 6.1 mm | 100 nF | 250 kHz | 5.2 µm | 250 N |

DCS3-252511C1 | 150V | 2.5 × 2.5 × 11.0 mm | 175 nF | 125 kHz | 9.2 µm | 250 N |

DCS3-030310C1 | 150V | 3.0 × 3.0 × 10.0 mm | 360 nF | 140 kHz | 8.8 µm | 360 N |

DCS3-030320C1 | 150V | 3.0 × 3.0 × 20.0 mm | 550 nF | 65 kHz | 19.8 µm | 360 N |

DCS3-030332C1 | 150V | 3.0 × 3.0 × 32.2 mm | 930 nF | 40 kHz | 33.0 µm | 360 N |

DCS3-050511C1 | 150V | 5.0 × 5.0 × 11.0 mm | 750 nF | 140 kHz | 9.5 µm | 1000 N |

DCS3-050520C1 | 150V | 5.0 × 5.0 × 20.1 mm | 1.5 µF | 70 kHz | 20.0 µm | 1000 N |

DCS3-050538C1 | 150V | 5.0 × 5.0 × 38.1 mm | 3.2 µF | 34 kHz | 40.0 µm | 1000 N |

DCS3-050552C1 | 150V | 5.0 × 5.0 × 52.2 mm | 4.5µF | 25 kHz | 55.0 µm | 1000 N |

DCS3-070712C1 | 150V | 7.0 × 7.0 × 12.0 mm | 1.4 µF | 130 kHz | 8.5 µm | 1960 N |

DCS3-070721C1 | 150V | 7.0 × 7.0 × 21.1 mm | 3.0 µF | 70 kHz | 19.0 µm | 1960 N |

DCS3-070739C1 | 150V | 7.0 × 7.0 × 39.1 mm | 6.0 µF | 35 kHz | 38.0 µm | 1960 N |

DCS3-070748C1 | 150V | 7.0 × 7.0 × 48.1 mm | 9.0 µF | 27 kHz | 50.0 µm | 1960 N |

DCS3-070793C1 | 150V | 7.0 × 7.0 × 93.5 mm | 16.0 µF | 14 kHz | 100.0 µm | 1960 N |

DCS3-101022C1 | 150V | 10.0 × 10.0 × 22.6 mm | 6.0 µF | 65 kHz | 20.0 µm | 4000 N |

DCS3-101040C1 | 150V | 10.0 × 10.0 × 40.7 mm | 13.0 µF | 34 kHz | 40.0 µm | 4000 N |

DCS3-101049C1 | 150V | 10.0 × 10.0 × 49.7 mm | 15.0 µF | 27 kHz | 50.0 µm | 4000 N |

DCS3-252511C1 | 150V | 2.5 × 2.5 × 11.0 mm | 175 nF | 125 kHz | 9.2 µm | 250 N |

Typical Applications

● Semiconductor Manufacturing: Mask stage micro-motion correction, wafer probe station precision alignment.

● Optical Instruments: Adaptive optics mirror actuation, laser beam stabilization, and focus control.

● Medical Devices: Ultrasonic scalpel transducers, endoscopic micro-drive modules.

● Industrial Automation: High-frequency valve control, active vibration suppression platforms.

● Aerospace: Satellite optical payload fine-tuning mechanisms, precision inertial navigation system compensators.